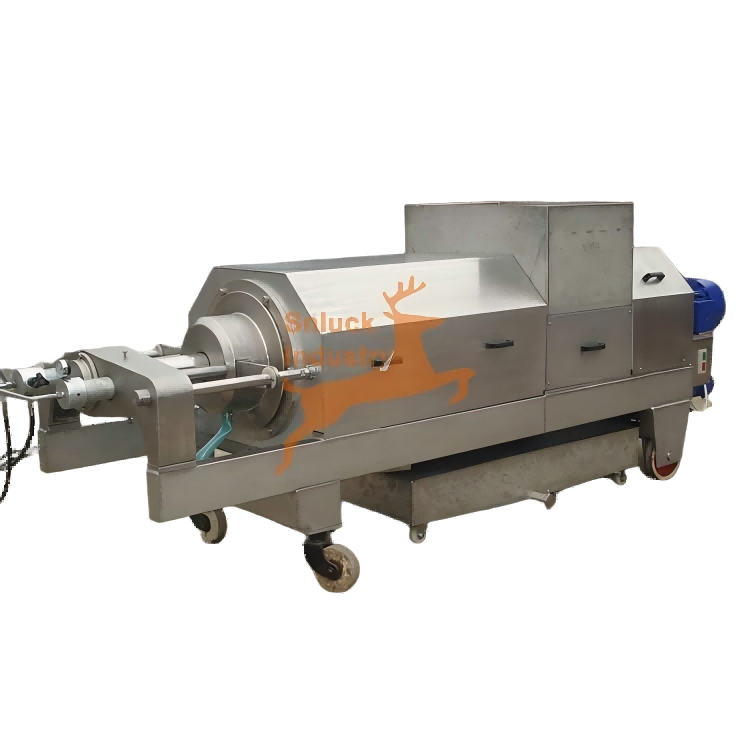

Separating Grater 82% yield, <18% pulp moisture.

Squeeze Out 15% More Juice—Leave Pulp 30% Drier. Unlock Hidden Yield.

200+ Customers

Game-Changer for High-Volume Labs: Reliable, Efficient, but Demands Space

As the facility manager of a mid-sized biomedical research center handling 500+ mice daily, we replaced manual cleaning with the eight months ago.