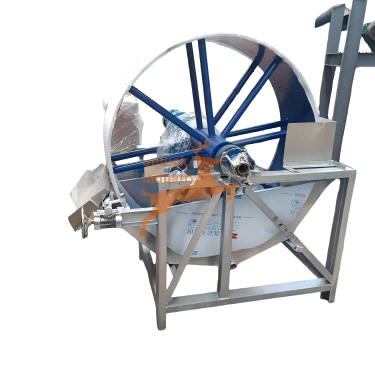

Vacuum Rotary Extractor Starch powder making(15% MC)

Gentle vacuum extraction preserves starch granules—boost yield 3% with ultra-white purity.

200+ Customers

3% Yield Boost from Day 1: Zero Granule Damage, Won Our First Order!

As a plant manager at ThaiStarch Co., switching from centrifuges to SnLuck's vacuum extractor was revolutionary:

- Gentle extraction: Starch granules remained intact—99.5% purity, 0.5% breakage (vs. 2% before).

- Plug-&-play: Installed during weekend maintenance, ran Monday's slurry at full capacity.

- Self-cleaning drum: No daily tear-downs, saving 3 hours/day.

Create with Passion Create with Passion Create with PassionCreate with Passion Create with Passion Create with Passion

Explore real-world applications across food, feed, and pharmaceutical industries.Explore real-world applications across food, feed, and pharmaceutical industries.

Turnkey Solutions

Providing end-to-end dehydration plants (cleaning→drying→packaging) with CE/FDA compliance – cutting energy costs 30% and eliminating policy risks for global clients.

Projects in 2024.

Gram be processed every seconds.