ECO (Economy) White Paper Less Consumption & Lower Labor Cost

ECO Heat Recovery Structure + AI-Driven Control System = Unbeatable ROI in 12-18 Months.

200+ Projects

Cut Drying Costs by 25% & Boost Output 20% – Our Cassava Plant's Energy Miracle!

ECO heat recovery cut our drying costs by 25%! Their AI control adapts to cassava moisture in real-time, slashing fuel use while boosting output 20%. Modular design let us retrofit old lines in 3 days. A game-changer for African processors!

| Innovation | Technical Implementation | Client Benefit |

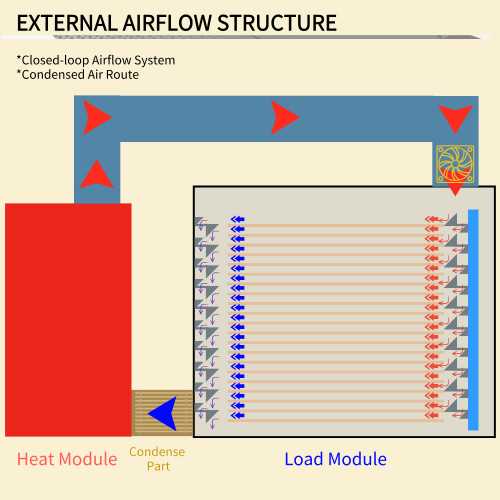

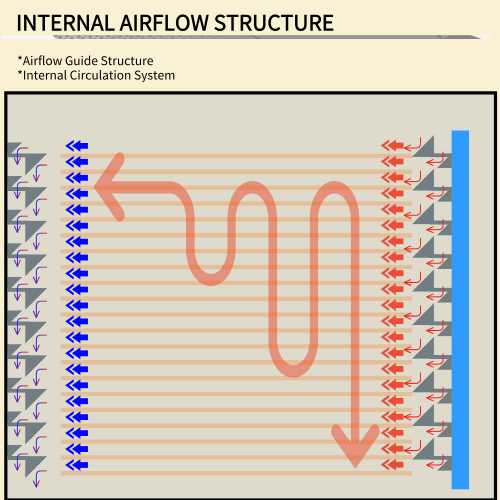

| Closed-Loop Heat Recovery | Condensing exhaust at 60°C → Preheat fresh air | 35% less energy input |

| AI Dynamic Control | LSTM models adjust temperature/humidity in real-time | 15% faster drying cycles |

| Modular Heat Sources | Plug-in heat pumps/solar/biomass modules | 40% fuel flexibility |

| Nano-Insulation | Aerogel panels (0.02W/m·K) + silicone seals | 8% less heat loss |