Parameter Table of Herb Drying

| Parameter | Traditional | SnLuck Solution | Improvement |

|---|---|---|---|

| Active Compound Retention | 70-85% | ≥95% | ↑25% potency |

| Microbial Safety | Log 3 reduction | Log 6 reduction | 99.9999% sterile |

| Drying Uniformity (RSD) | >15% | <5% | ↓66% deviation |

| Residual Solvents | 500-800 ppm | <50 ppm | ↓90% contaminants |

Pain-Point vs. Solution

| Herb Industry Pain Points | SnLuck Solutions | Quantified Results |

|---|---|---|

Bioactive Degradation Bioactive Degradation |

Low-Temp Anaerobic Drying Low-Temp Anaerobic Drying |

► Rosmarinic acid ≥95% (HPLC) |

Microbial Contamination Microbial Contamination |

Isolator Technology + UV-C Isolator Technology + UV-C |

► TAMC/TYMC: <10 CFU/g |

Inconsistent Potency Inconsistent Potency |

Real-time NIR Potency Monitoring Real-time NIR Potency Monitoring |

► RSD<5% across batches |

Traceability Gaps Traceability Gaps |

Blockchain Batch Tracking Blockchain Batch Tracking |

► Full genealogy in 3 clicks |

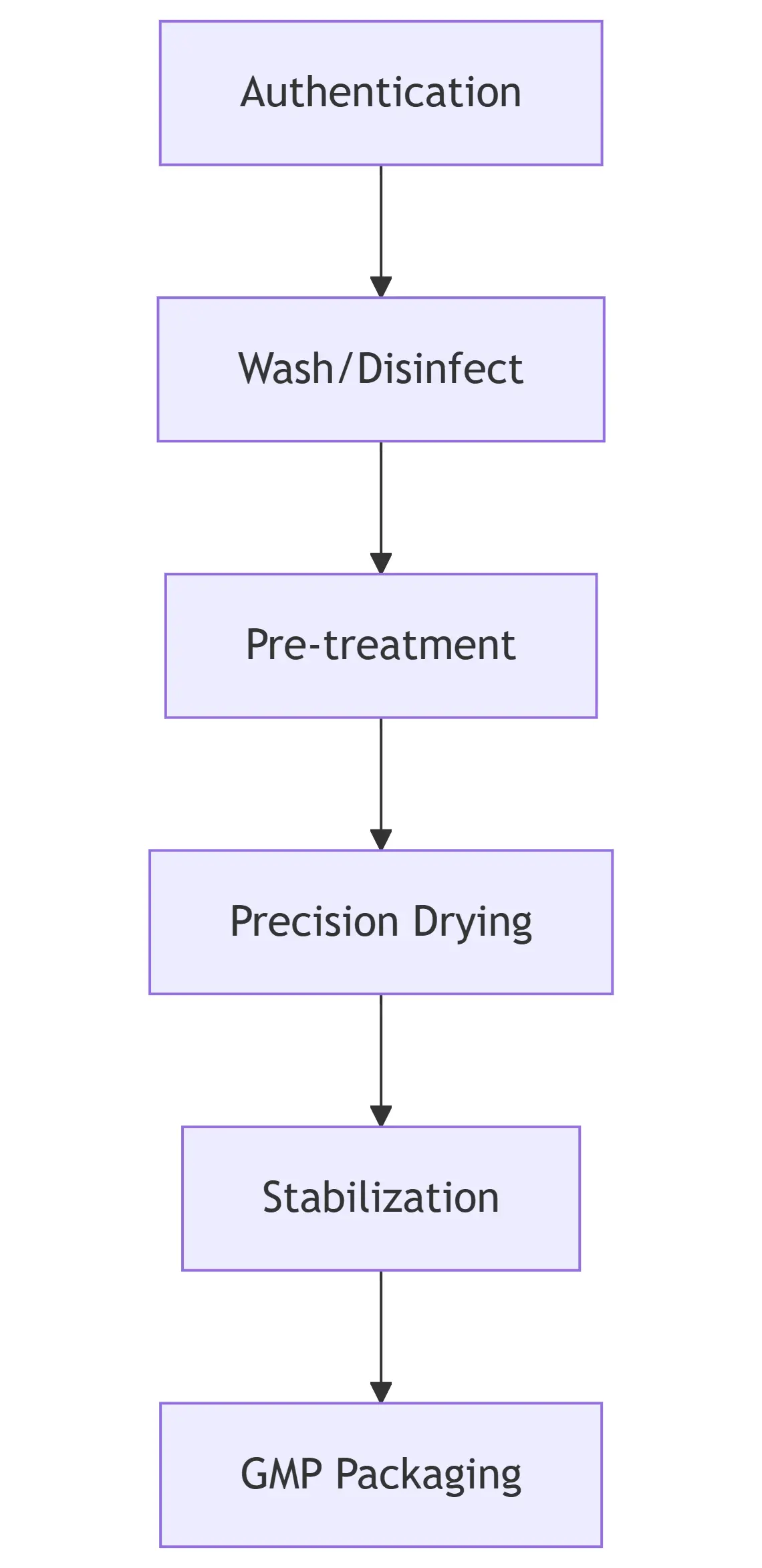

Herb Process Line

GMP Herb Processing: 98% Active Compound Retention, 50% Energy Reduction, Full Traceability Reviews

400+ Customers

From 62% to 98% Active Compound Retention

As Quality Director at NordicBotanics AB (Stockholm), we struggled for years with inconsistent echinacea purpurea extracts. Traditional drying destroyed 38% alkylamides - our key immunomodulatory compounds.