Continuous Belt Dehydrator is

An Industrial-scale precision drying

24/7: Multi-tier conveyor belts with IoT-controlled hot air circulation for continuous, energy-efficient dehydration.

| Parameter | Range | Precision | Value for Your Project |

|---|---|---|---|

| Temperature | -15°C to 120°C | ±0.5°C | Low heat drying to high-temp curing |

| Humidity Control | 2%–95% RH | ±1.5% RH | Prevents over-drying or condensation |

| Airflow Volume | 2,000–30,000 CFM | ±5% flow rate | Uniform drying across 12+ belt layers |

| Belt Speed | 0.02–8 m/s | ±0.01 m/s | Adapts to material moisture sensitivity |

| Drying Uniformity | CV ≤1.5% | N/A | Eliminates corner hotspots |

| Parameter | Range | Precision | Value for Your Project |

|---|---|---|---|

| Temperature | -15°C to 120°C | ±0.5°C | Low heat drying to high-temp curing |

| Humidity Control | 2%–95% RH | ±1.5% RH | Prevents over-drying or condensation |

| Airflow Volume | 2,000–30,000 CFM | ±5% flow rate | Uniform drying across 12+ belt layers |

| Belt Speed | 0.02–8 m/s | ±0.01 m/s | Adapts to material moisture sensitivity |

| Drying Uniformity | CV ≤1.5% | N/A | Eliminates corner hotspots |

| Energy Efficiency | 3.8–4.2 L/kWh (water extraction) | N/A | 30% lower than conventional dryers |

Bachelor Degree Employeers

R&D Expenditure Ratio

Continuous Belt Dehydrator Supports

Great Results

Precision Outcomes, Not Just Output

| Parameter | Industry Standard | SnLuck Performance | Improvement |

|---|---|---|---|

| Moisture Control | ±3% | ±0.5% | +83% accuracy |

| Color Retention | 85-90% | ≥95% | +10% vibrancy |

| Breakage Rate | 5-8% | <1% | -87% loss |

Bachelor Degree Employeers

R&D Expenditure Ratio

Lower Consumption

Smart Labor + Minimal Waste = True Sustainability

| Optimization Area | Traditional System | SnLuck Solution | Improvement |

|---|---|---|---|

| Energy Consumption | High volatility + waste | AI-driven stability | ↓30-70% cost |

| Labor Efficiency | Manual-intensive checks | Automated control | ↓50-90% workload |

| Loss Rate Control | Frequent downtime + waste | Predictive prevention | ↓75-88% loss |

Bachelor Degree Employeers

R&D Expenditure Ratio

Simpler Operation

Select any material to see how SnLuck automates optimal settings - no engineering degree required!

| Operation Parameter | SnLuck Continuous Dryer | Traditional Dryers | Improvement |

|---|---|---|---|

| Startup Time | ≤5 minutes | 30+ minutes | ↓83% |

| Preset Programs | 400+ material profiles | Manual settings only | ∞ presets |

| Parameter Adjustment | 1-touch sync (belt speed/temp/humidity) | Separate controls per parameter | ↓70% steps |

| Training Required | ≤2 hours | 3-5 days | ↓92% |

| Error Recovery | Auto-resume with 30-min memory | Full restart required | 100% continuity |

Bachelor Degree Employeers

R&D Expenditure Ratio

Continuous Belt Dehydrator available for

Bachelor Degree Employeers

R&D Expenditure Ratio

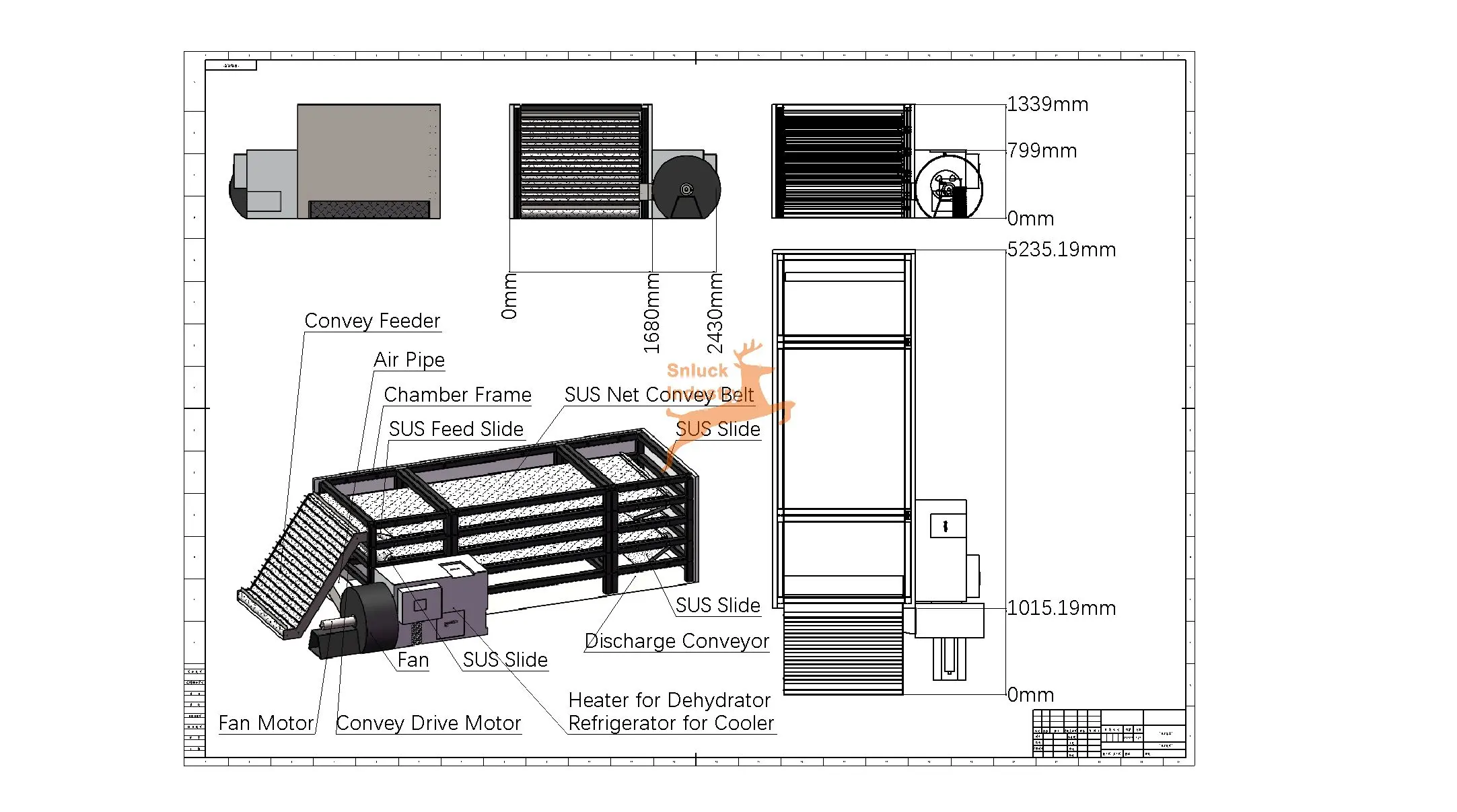

Continuous Belt Dehydrator models

| Capacity | Model S/N | Suits | Configuration |

| 100-200Kg/Hr | SL-CSSX-L1 | Farm Hold | Size: 4*2.2*2.2CBM | Module: 1*Heat module, 1*Drive module , 1*Load module | Drive power: 5-11Kw |

| 200-400Kg/Hr | SL-CSSX-L2 | Workshop Plant | Size: 5.6*2.2*2.2CBM | Module: 1*Heat module, 1*Drive module , 2*Load module | Drive power: 7-15Kw |

| 300-600Kg/Hr | SL-CSSX-L3 | Small Collective | Size: 8.8*2.2*2.2CBM | Module: 1*Heat module, 1*Drive module , 3*Load module | Drive power: 9-17Kw |

Continuous Belt Dehydrator Reviews

200+ Projects

Where Continuous Motion Meets Sustainable Drying — Elevating Efficiency, Preserving Value.

Food factories value its fully automated belt flow and uniform drying (±1.5% RH control). Large-scale plants report zero manual intervention, with multi-layer penetration eliminating corner hotspots. Energy consumption drops 30% via closed-loop heat recovery—modular design adapts to mass production. Ideal for 10+ ton/day throughput of leafy greens/herbs; batch types fit R&D trials better.