Monitor and Control Need

Real-Time Data Through Sensor Monitoring

- Temperature: Multiple sensors positioned within the drying chamber and potentially even embedded in the conveyor belt itself provide a comprehensive picture of the temperature distribution throughout the dehydrator.

- Humidity: Sensors dedicated to humidity monitoring track the moisture levels within the drying chamber. This real-time data is crucial for controlling the drying process and preventing over-drying or under-drying of the product.

- Product Flow: Additional sensors can be integrated into the conveying system to monitor product flow.

Benefits of Real-Time Data

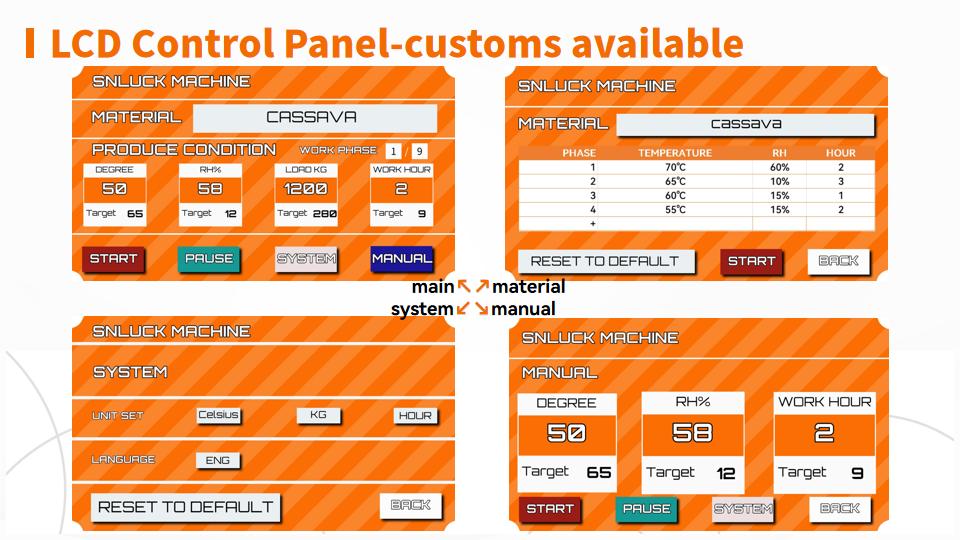

- Process Control: Real-time data allows for adjustments to be made to temperature, humidity, and potentially even conveyor speed on the fly.

- Data-Driven Decisions: The ability to track trends and analyze historical data empowers operators to refine drying profiles for different materials.

- Predictive Maintenance: By monitoring sensor data over time, potential issues within the dehydrator or conveying system can be identified early on.

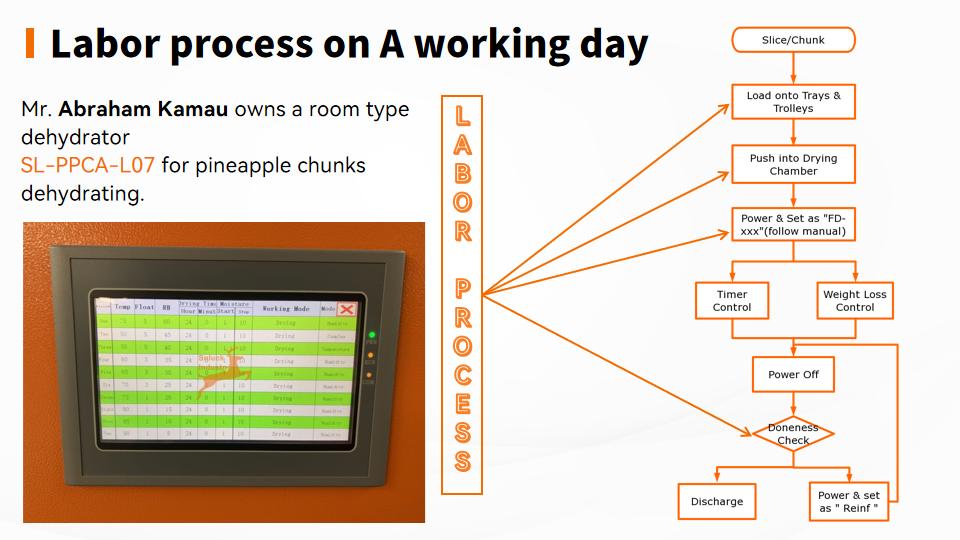

User-friendliness of the monitoring system