Since 2010

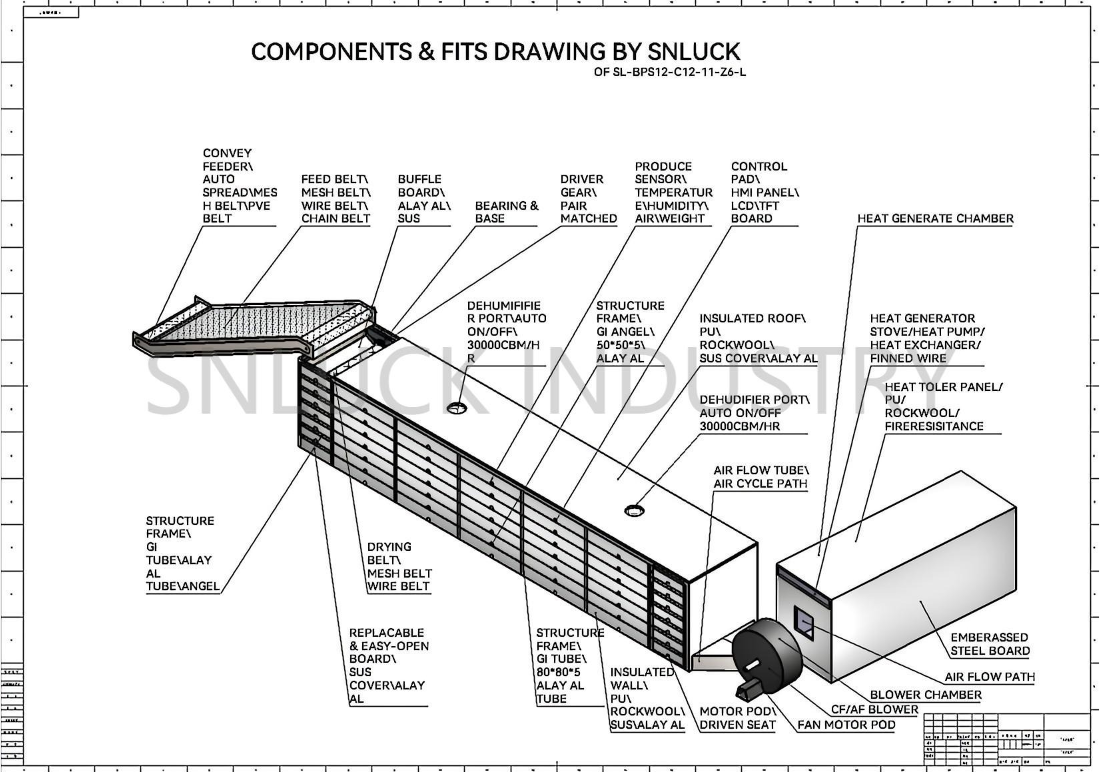

Snluck has been dedicated to researching & manufacturing top-quality dehydrating equipment.

@ temperature\humidity\period\unattend FOR easy-eco-earn produce.

3 Primary Supports

A right one, a good one, a reliable one.

5 Supreme Capability

Easy have, easy use, easy operate, easy maintenance.

Passionate – Dedicated – Professional

its’ not about anything,

it’s about ‘YOU’!

Our partnership is not just about delivering a top-notch dehydration system; it’s about forging a strong alliance that understands your unique challenges and aspirations, ensuring a customized solution that propels your business forward.

Passionate – Dedicated – Professional

the approach we follow

Embarking on a new food processing project requires careful planning and execution. Our comprehensive process ensures a seamless transition from initial concept to successful operation. Let’s delve into the key stages of our project confirmation process.