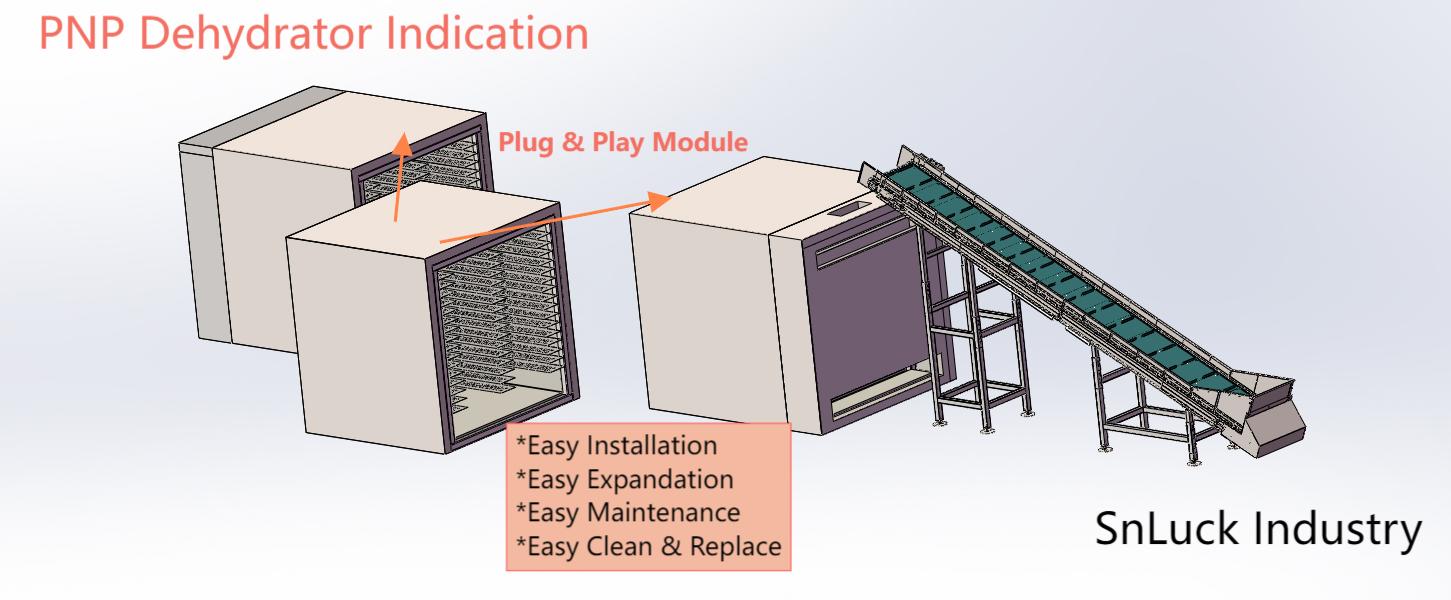

Plug & Play Module Make Better Produce By-

4 Feature

Plug & Play Module Contributes to -

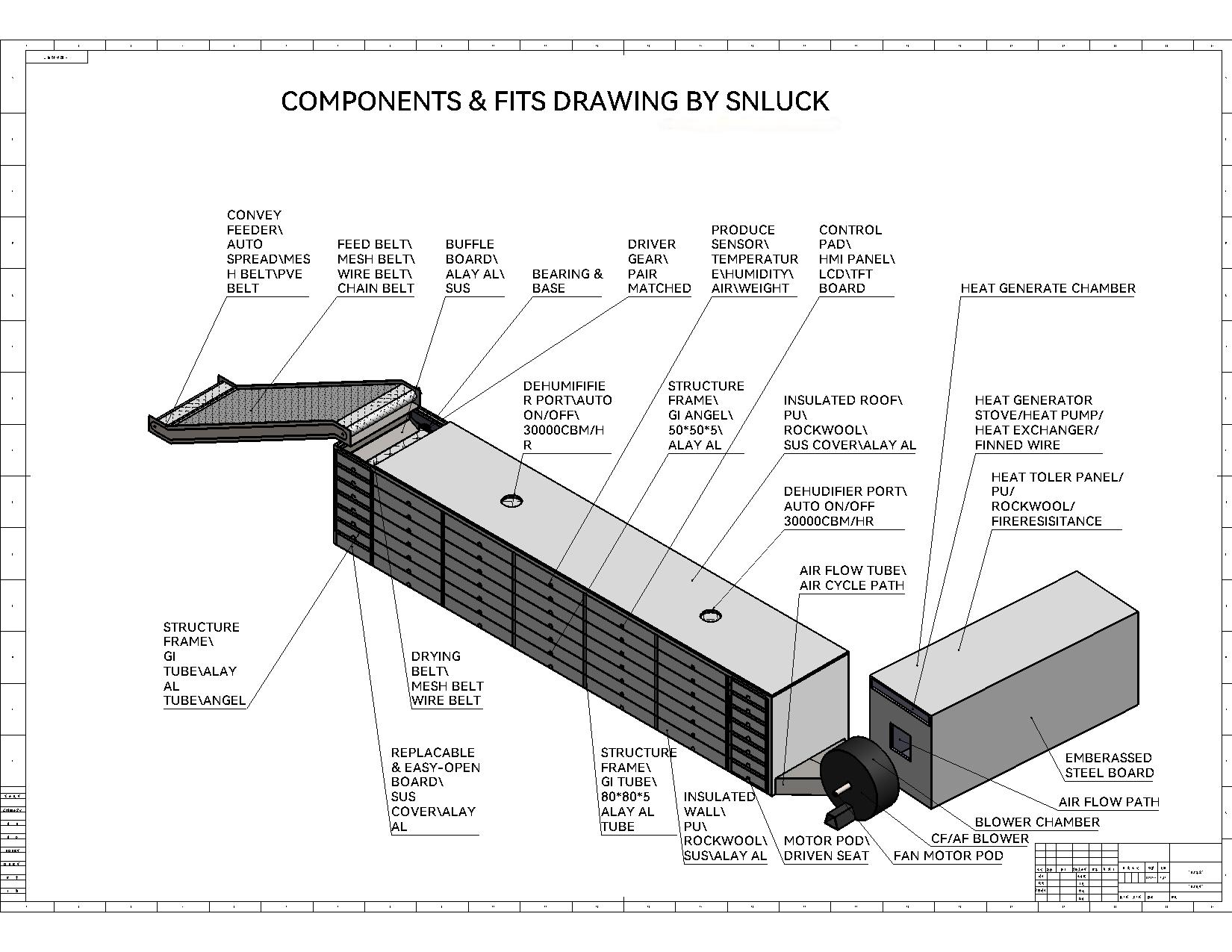

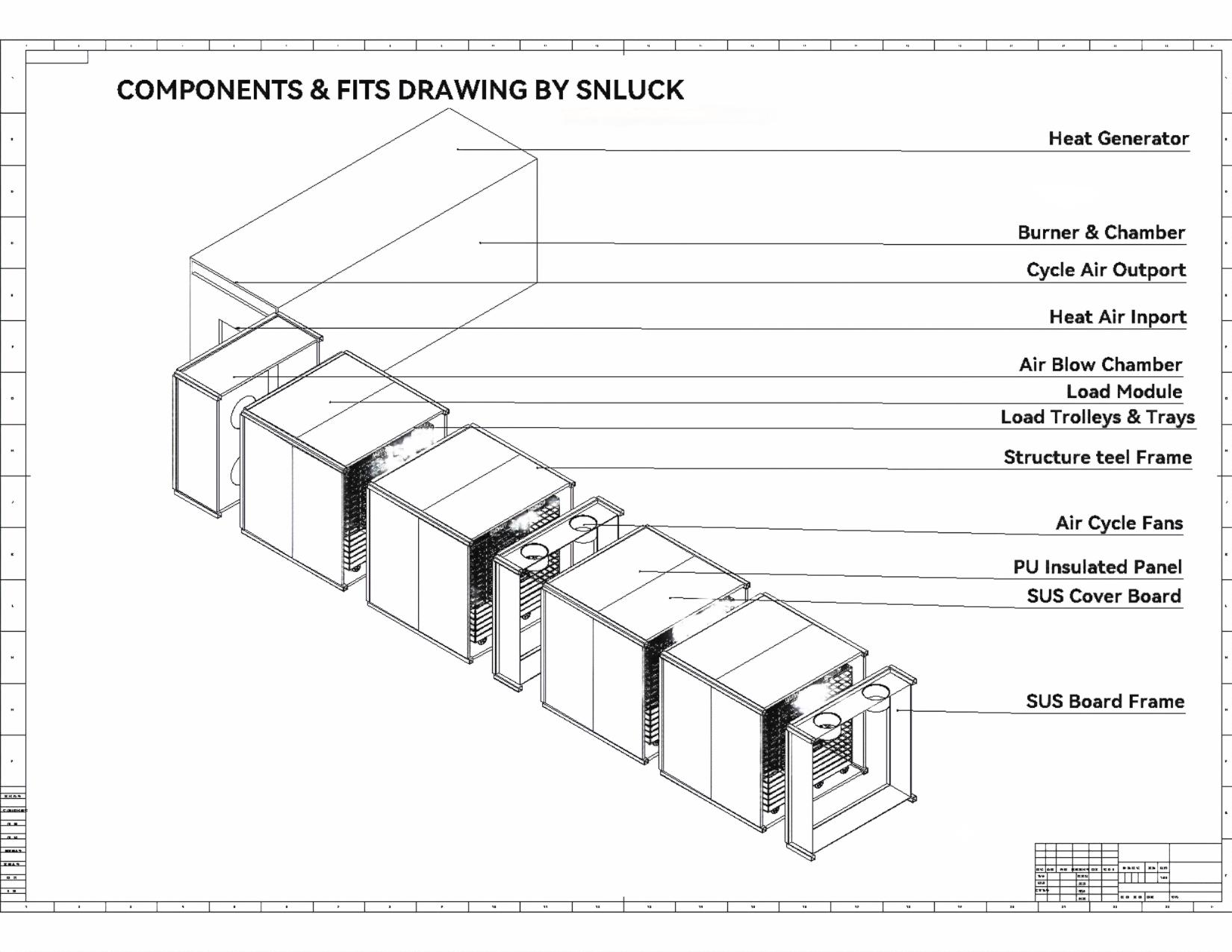

Equipment

review and comments on the Plug & Play Module -

what people are saying

The dehydrator equipment provided by your company has been a game-changer for our food processing project, the precision and consistency it delivers have enabled us to enhance our product quality while significantly reducing waste.

Helen Okfusky – CTO of Natural Food pvt.

We were looking for a solution that would simplify our drying process without compromising on results, your dehydrator equipment has exceeded our expectations, making the entire operation not only more efficient but also much easier to manage.

Jane K. Smith – Head of Tomorrow Going Product Co.,