Continuous Belt Dryer Achieves Well-dry @

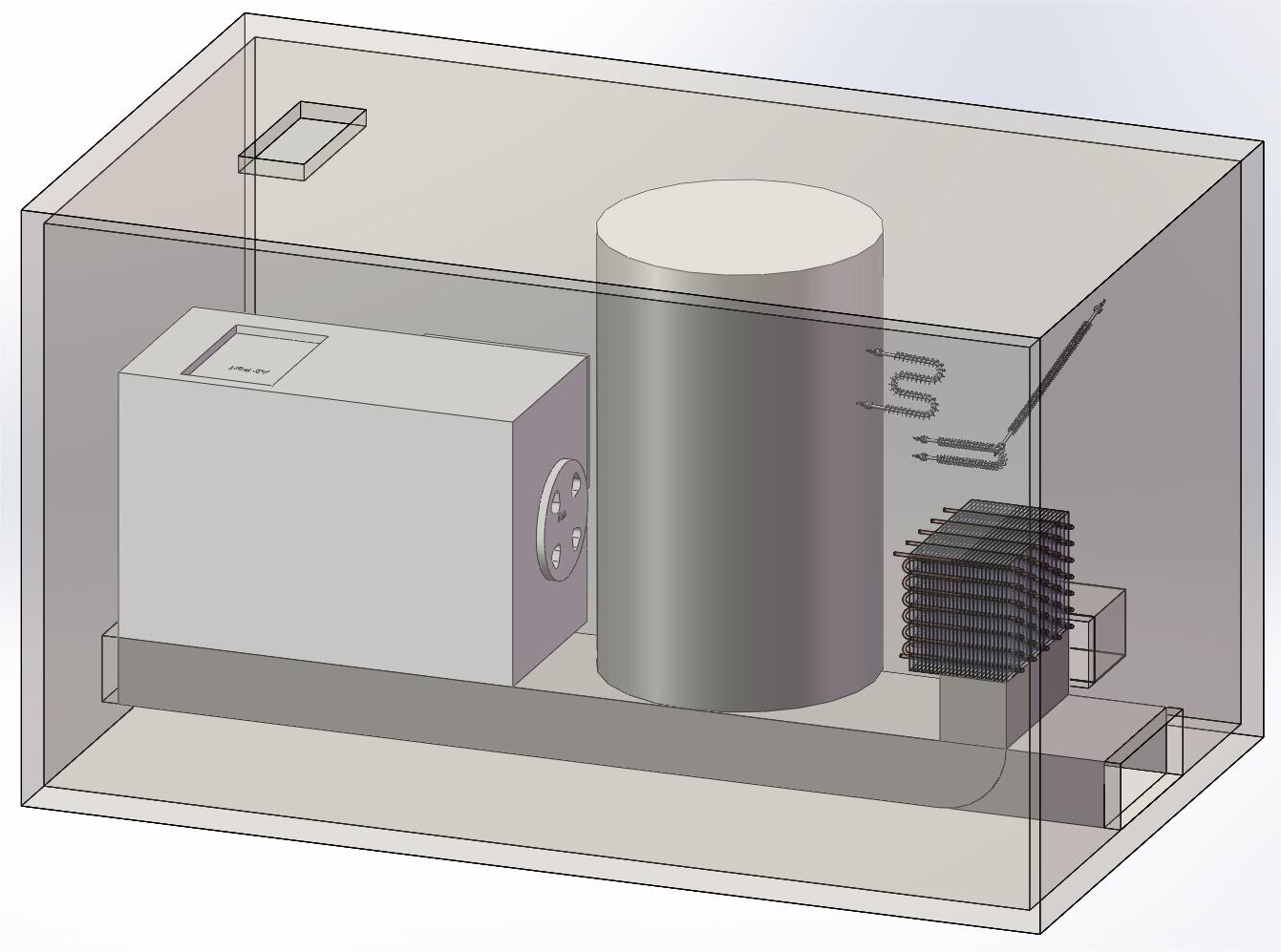

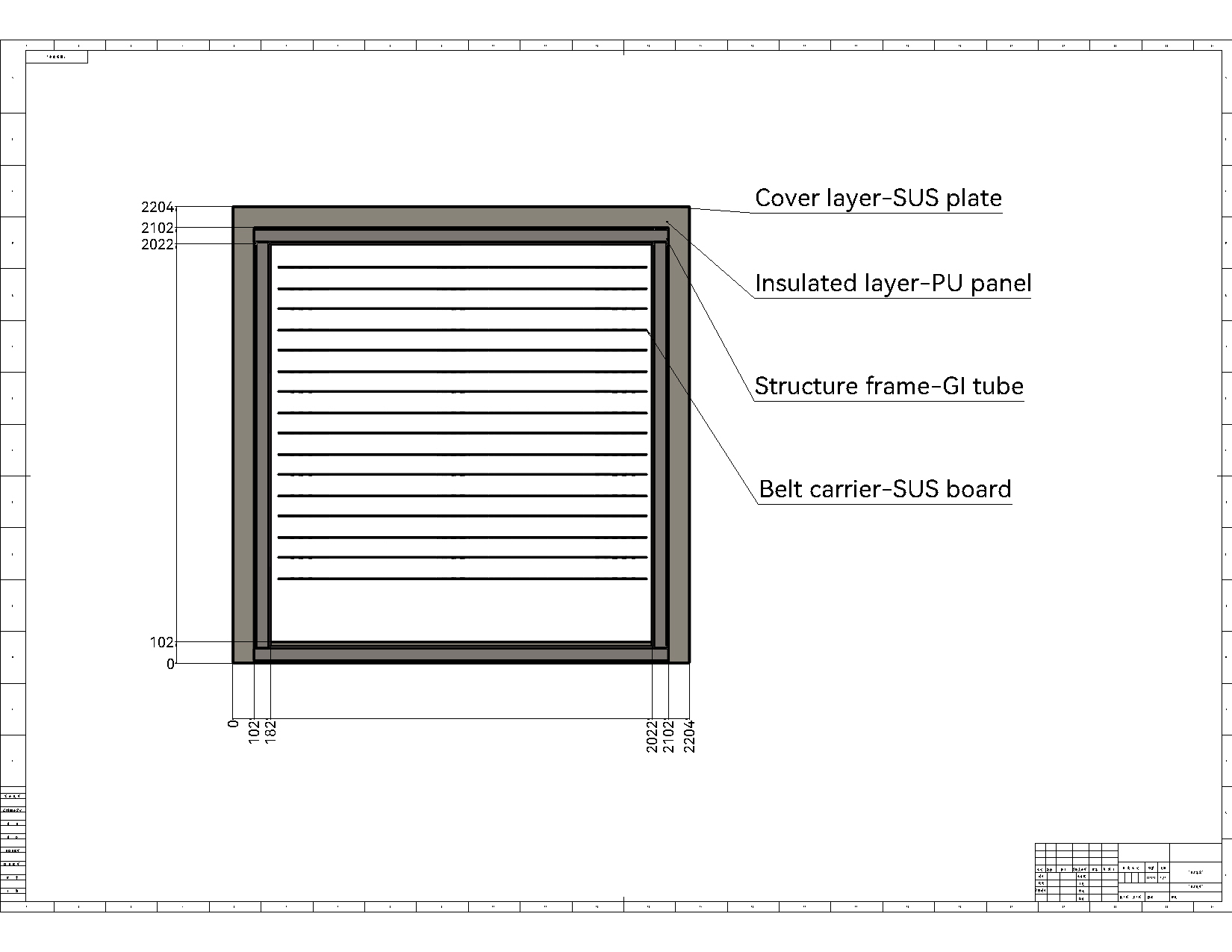

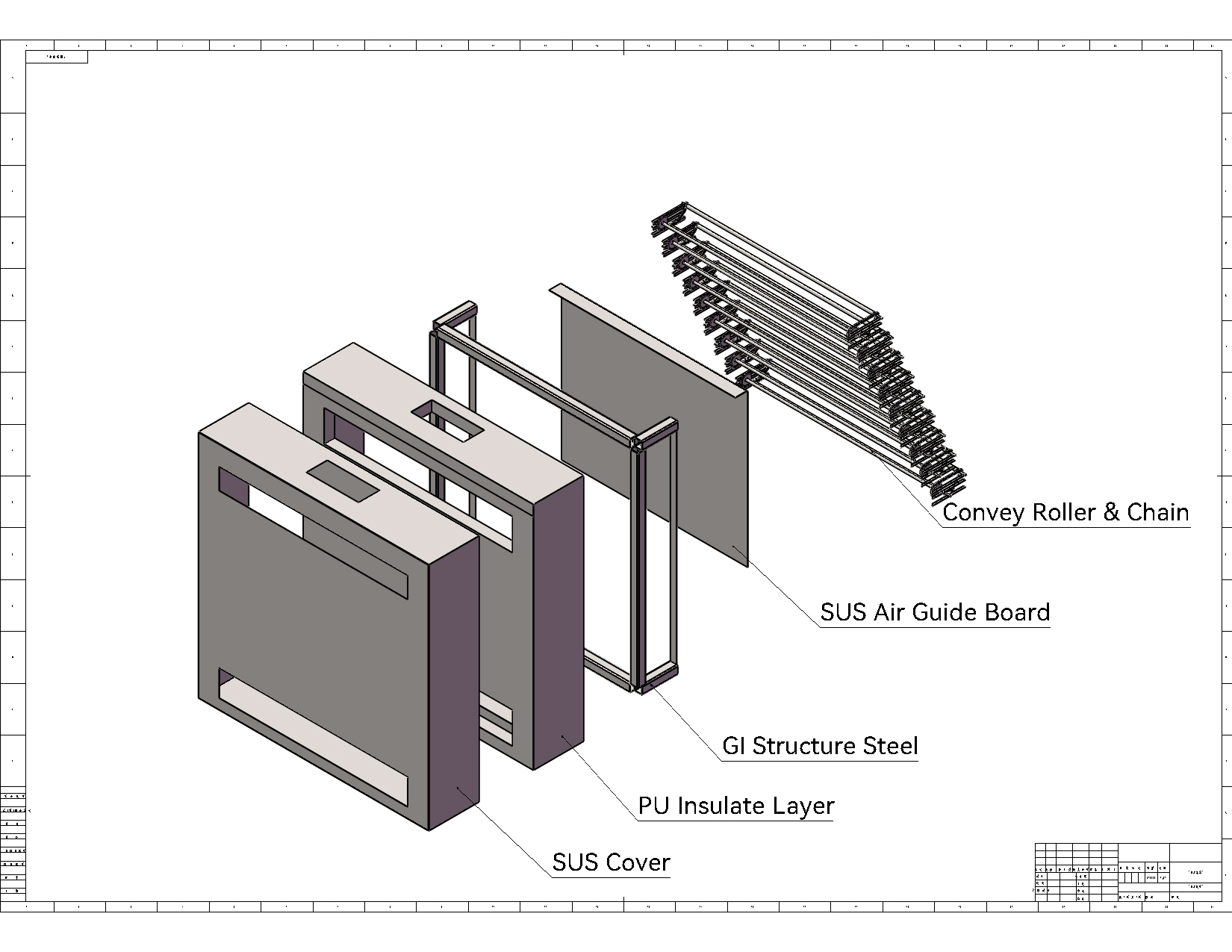

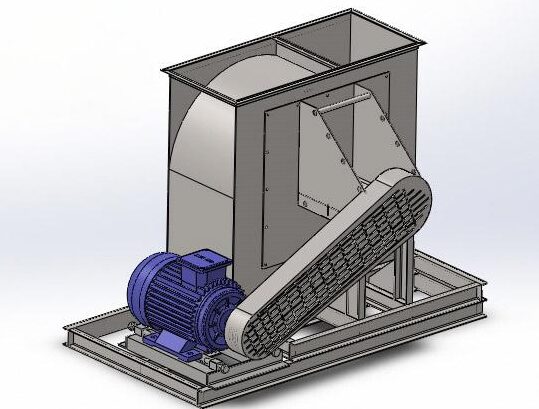

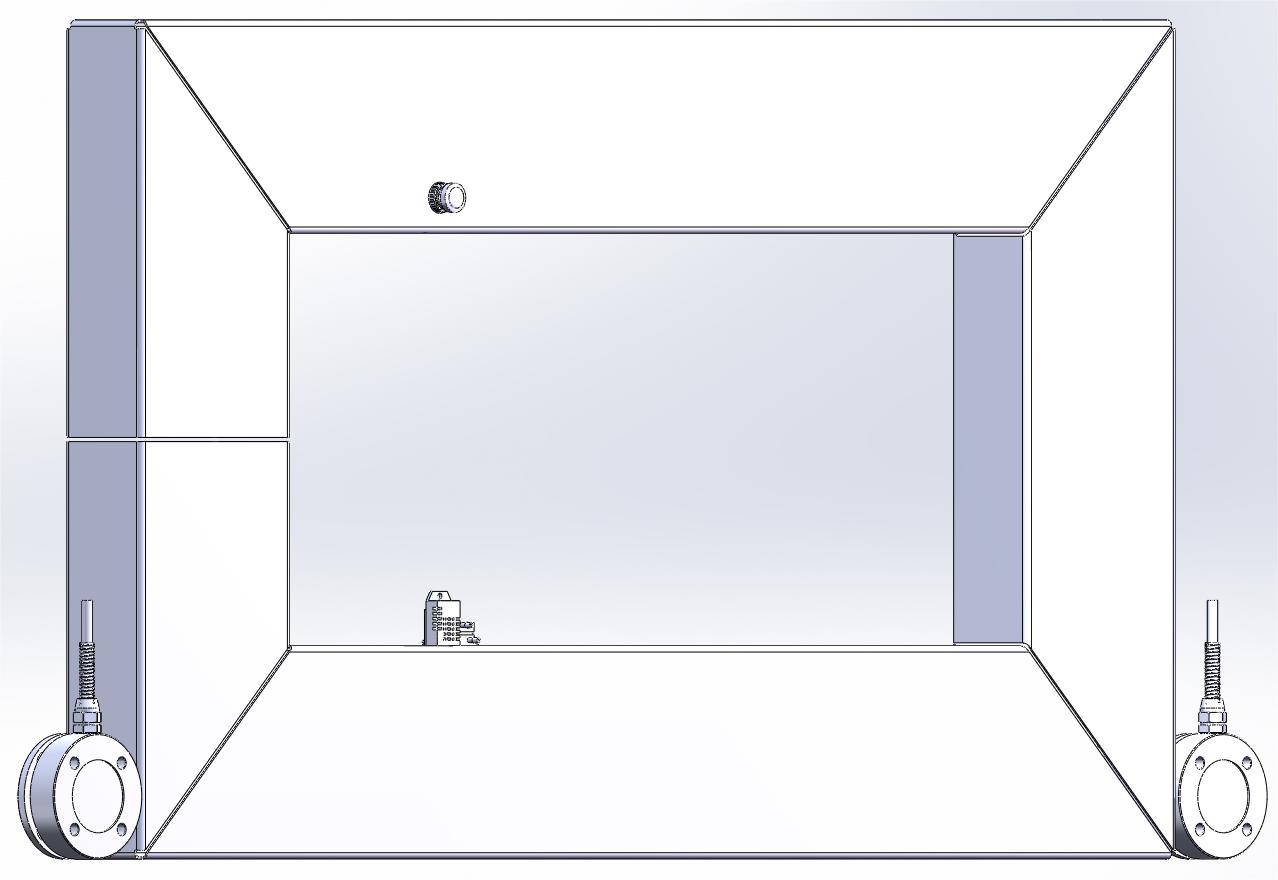

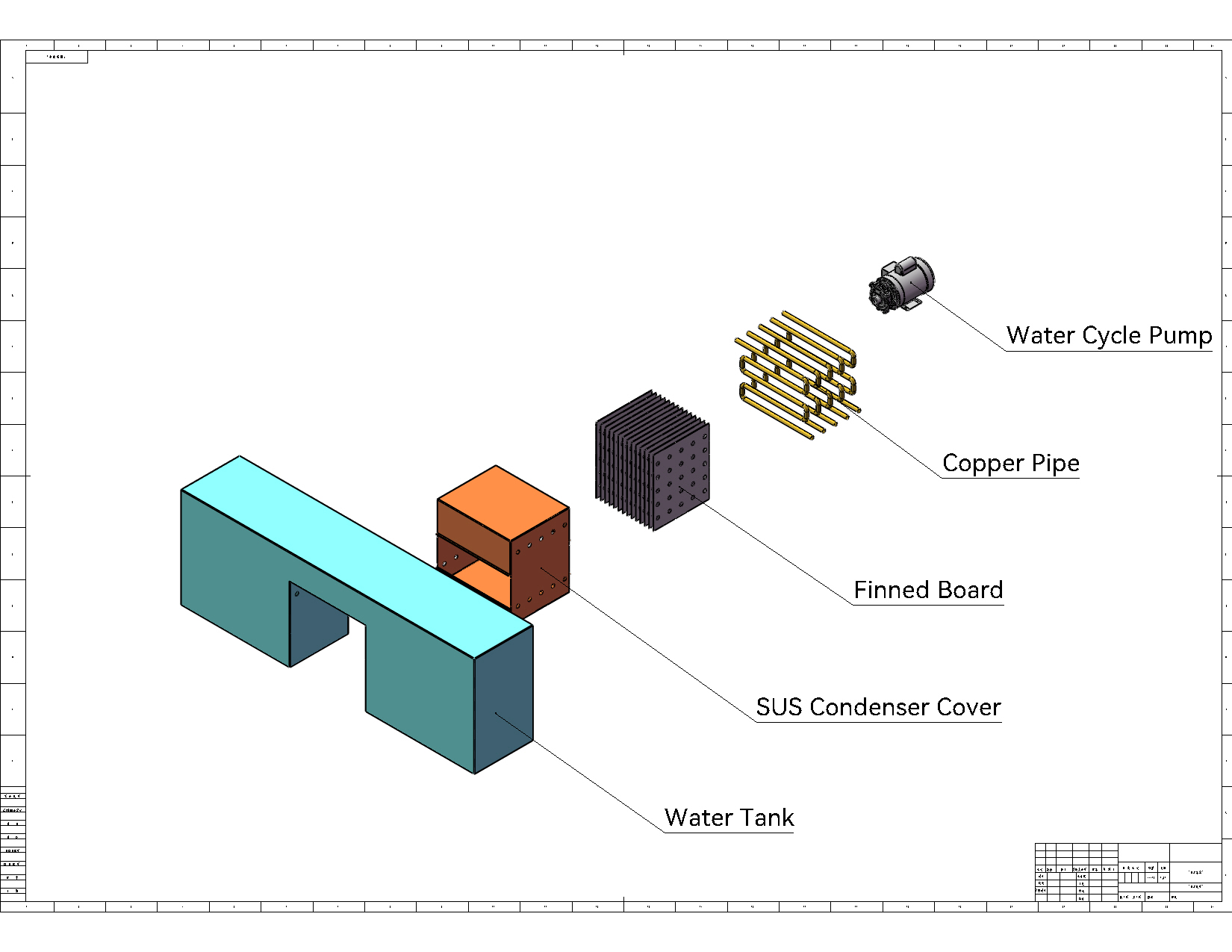

Streamlined Structure of Continuous Belt Dryer -

ConDry™ Modules & Parts

Models & Customization of Continuous Belt Dryer -

Specification Comparison

Larger capacity & efficiency At same size: 11*2*2CBM dimension & 12*2sqm occupied area.

| Item | Standard Model SL-BPCX-A2G | Rehanced Model SL-CSPX-L5 |

|---|---|---|

| **Regular Parameter** | ||

| Capacity | 6-12Mt/24Hr | 10-20Mt/24Hr |

| Hot Air Temp Range | 40-120℃ | -15-135℃ |

| Load Layers | 3-12 Layers | 3-16 Layers |

| **Structural Feature** | ||

| Valid Area in Single Layer | 20SQM | 32SQM |

| Thickness Loading | <25mm | <50mm |

| Module Assemble Period | 48Hr | 72Hr |

| **Heat Efficiency** | ||

| Heat Power Efficiency | 78% | 82% |

| Heat Recycle Ratio | 65% | 77% |

| **Control Accuracy** | ||

| Temp Fluctuation Control | ±2℃ | ±1℃(PID 2.0) |

| Convey Speed Adjusting | ±1m/Hr | ±0.5m/Hr |

Purchasers have access to a comprehensive life span support service, including pre-sale consultation, installation and commissioning, ongoing technical support, and after-sales services.

The dehydrator is suitable for a wide range of agricultural and industrial products, including fruits, vegetables, herbs, and other organic materials.

By utilizing efficient heat transfer systems and intelligent control algorithms, the dehydrator minimizes energy consumption, leading to reduced operating costs over time.

The company offers customized solutions based on individual requirements, ensuring that the dehydrator selected will perfectly suit the intended application and operational scale.

The dehydrator operates by circulating hot air through the product, which removes moisture and dries the material. This process helps in preserving the product and extending its shelf life.