This guide is designed to empower you, the industrial dehydrator user, to achieve your desired product outcome with efficient operation and cost-effective practices.

Understanding Your Dehydrator

- Module-Based Construction: Explore the benefits of modular design, including scalability, easier maintenance, and future-proofing your investment. Explain how modules can be added or replaced to adapt to changing production needs.

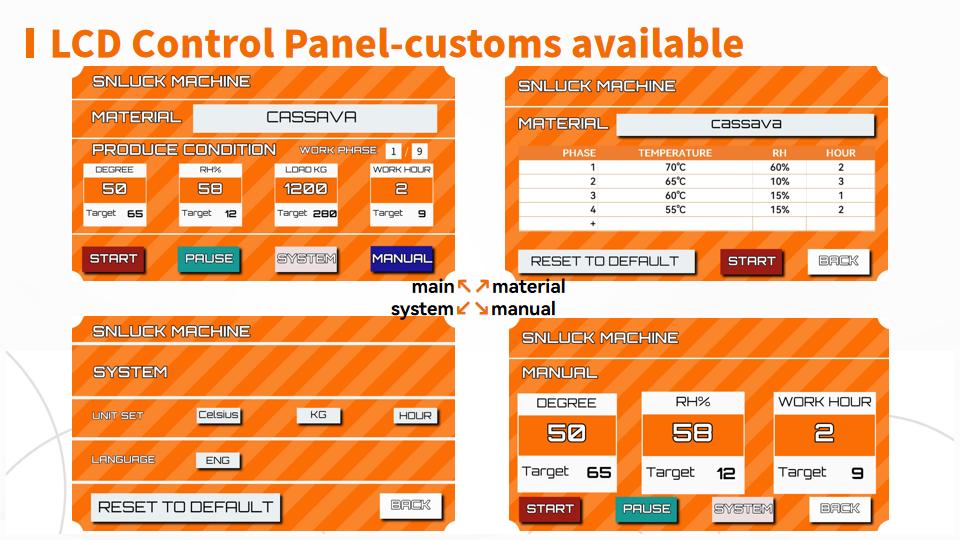

- IoT Control: Discuss the advantages of internet-of-things (IoT) integration, such as remote monitoring, data collection, and potential for process optimization.

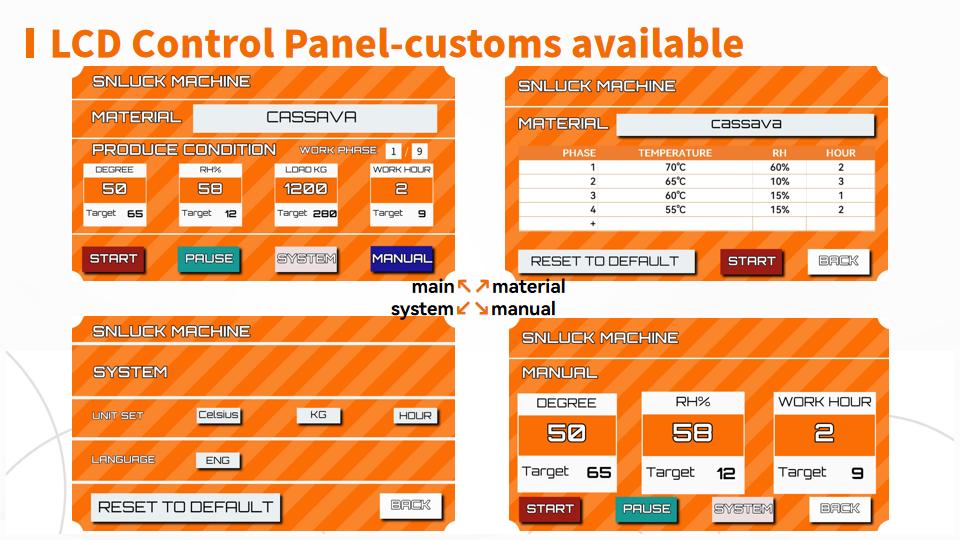

- Sensitive Temperature Control: Explain the importance of precise temperature control for consistent drying results and product quality. Highlight the dehydrator’s capabilities in maintaining accurate temperature settings.

- Massive Data Guide (Optional): If your dehydrator offers data logging or analysis features, explain how this data can be used to optimize drying parameters, reduce waste, and improve overall efficiency.

Optimizing Dehydration for Your Product

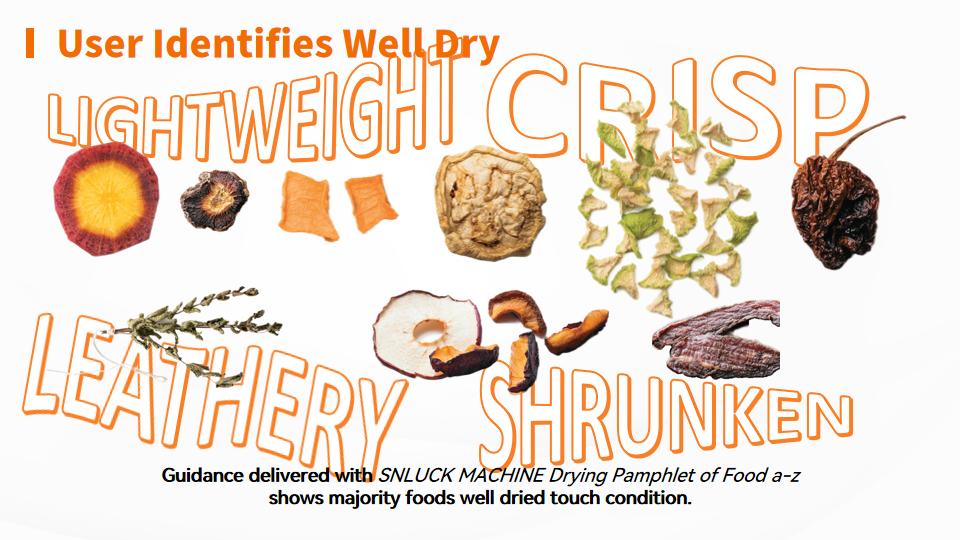

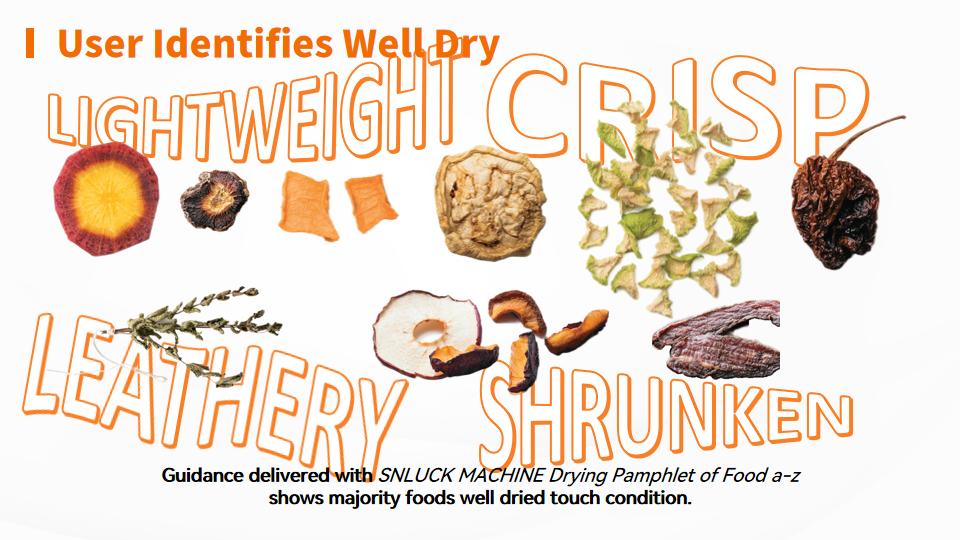

- Understanding Your Product: Emphasize the importance of understanding your product’s specific drying characteristics, such as ideal final moisture content and temperature sensitivity.

- Selecting the Right Drying Parameters: Guide the user on choosing the appropriate temperature, airflow settings, and drying time based on their product and desired outcome.

- Loading Techniques for Optimal Airflow: Provide tips on efficient tray loading techniques to ensure proper air circulation and achieve uniform drying throughout the product.

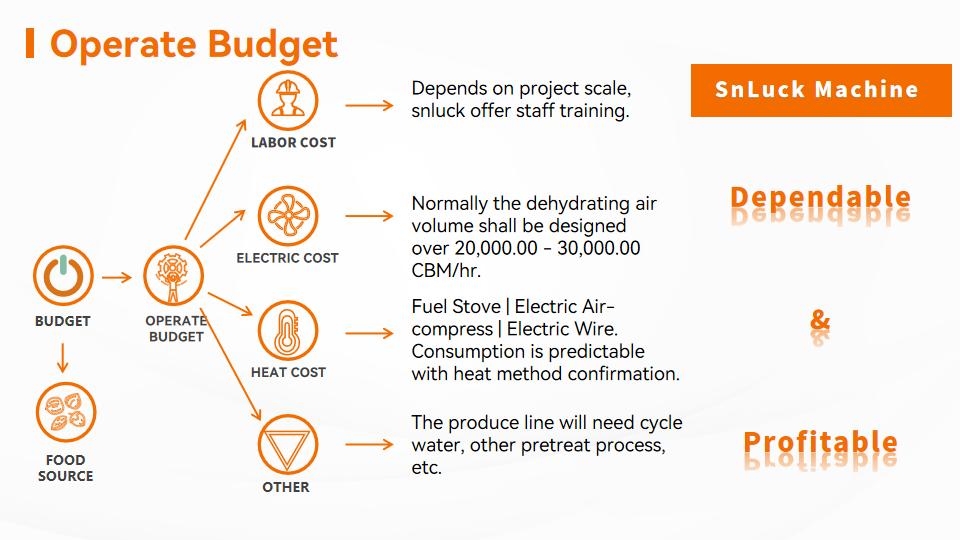

Cost-Effective Operation

- Minimizing Energy Consumption: Discuss strategies to reduce energy usage, such as utilizing waste heat from higher temperature zones (if applicable) or optimizing drying cycles.

- Preventative Maintenance: Highlight the importance of regular maintenance for smooth operation, energy efficiency, and extending the lifespan of your dehydrator.

- Optimizing Throughput: Offer guidance on maximizing production capacity while maintaining product quality, potentially through batch scheduling or adjusting conveyor belt speed (for continuous dehydrators).

Additional Considerations

Safety Protocols: Briefly outline essential safety precautions to follow when operating the dehydrator.

Troubleshooting Tips: Provide basic troubleshooting steps for common issues users might encounter. 1. Online Support-2. Live Video Guidance-3. Onsite Support.

Customer Support: Inform the user of available customer support channels for further assistance or technical questions. 1.Presale Consult-2.Commission Manage-3.Aftersale Support.