Batch Tray Dryer Achieves Well-dry @

- 1

Material: Up to 104 Materials Available.

- 2

Scale: 300Kg to 50 MT Daily Capacity Single Set

- 3

Memory: Auto Recovery Function

- 4

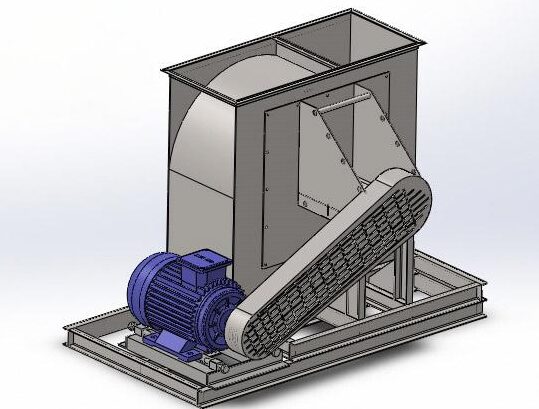

In/Out: Manual Load & Discharge System with Even Spreader

- 5

Break: Breakage Ratio <3%

- 6

Protect: Accurately Temp & Humi Control

- 7

Extend: Module Add or Replace in 2 Hours

- 8

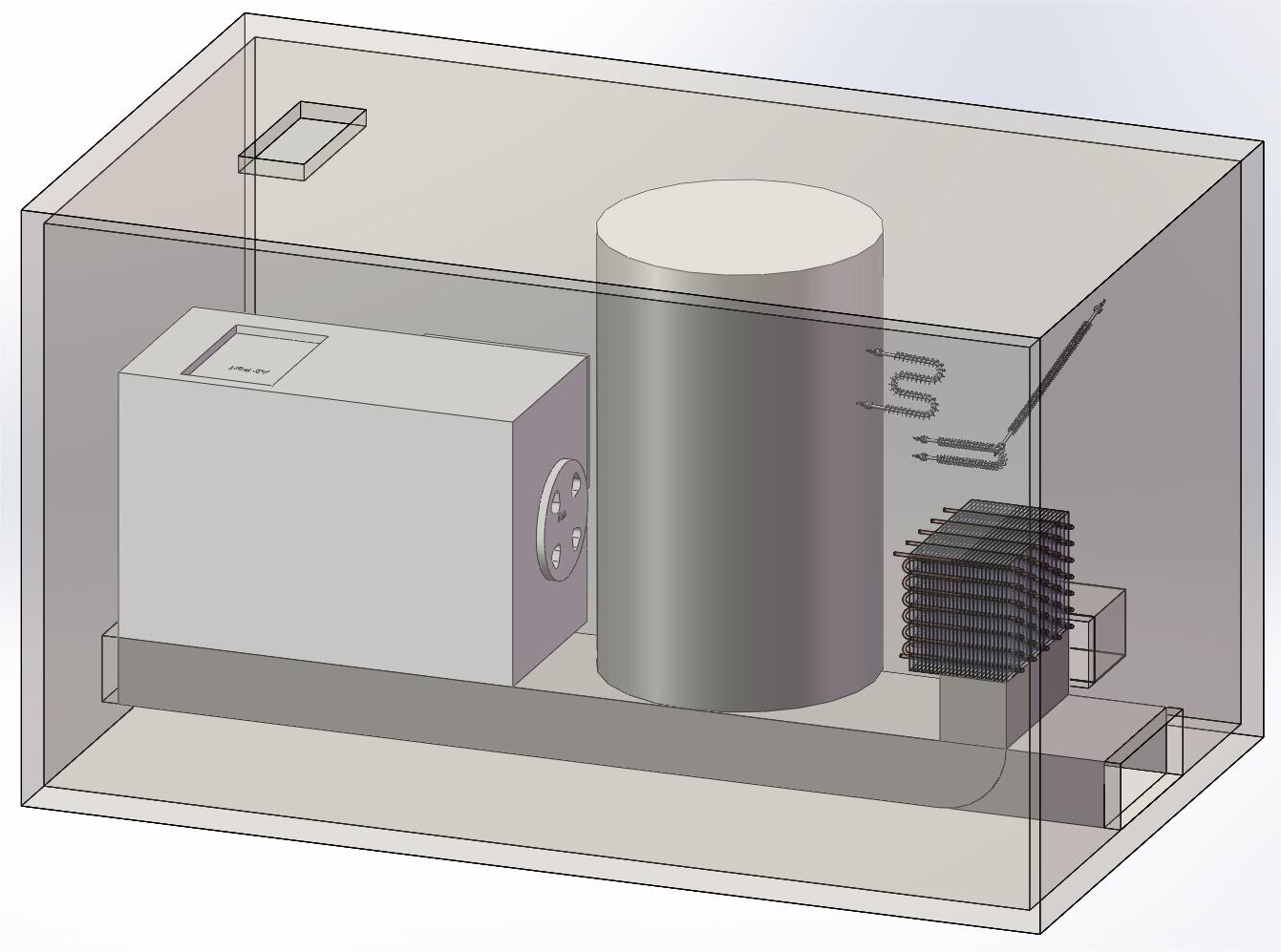

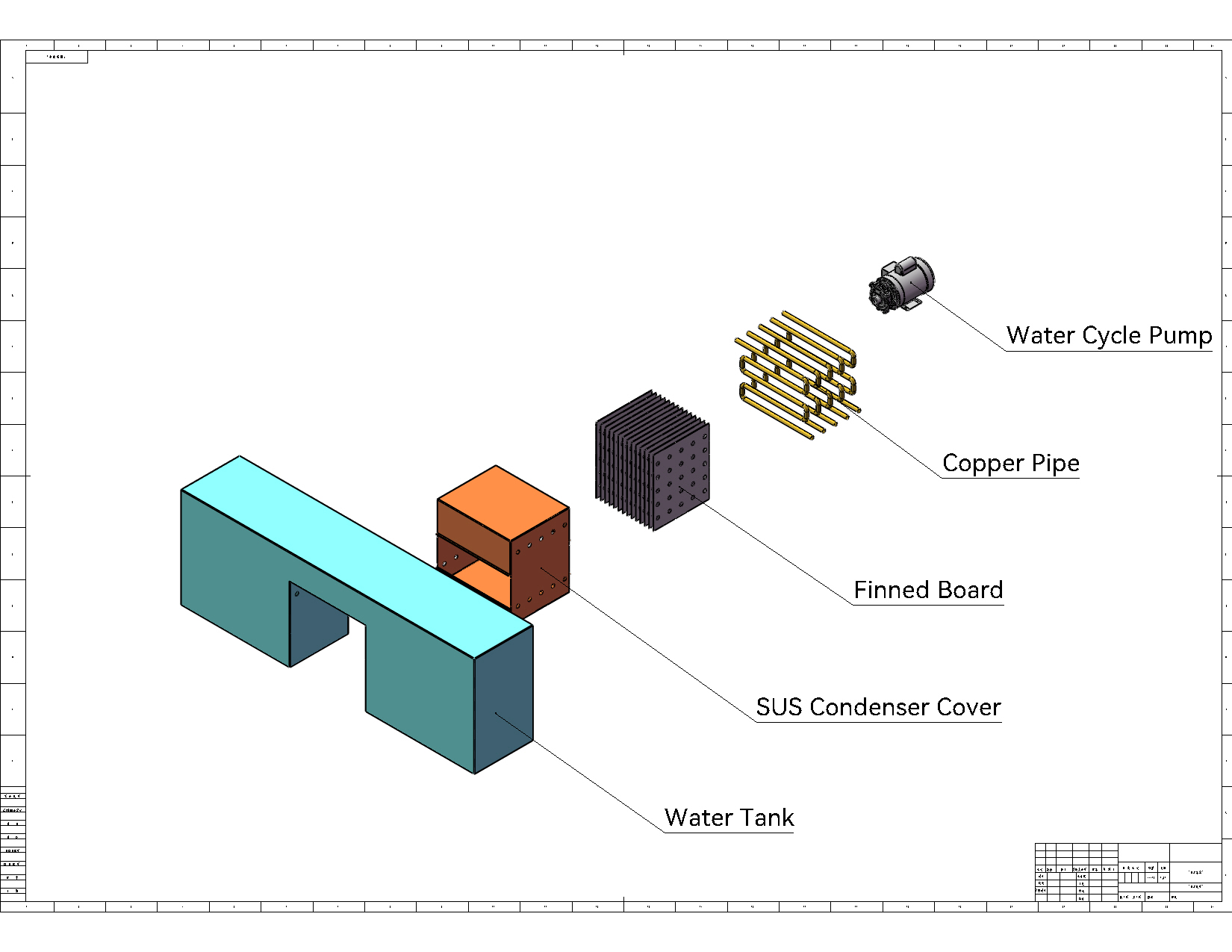

Eco: ConDry™ Technique for Energy Saving

- 9

Smart: 6 Months Data Storage & Analysis

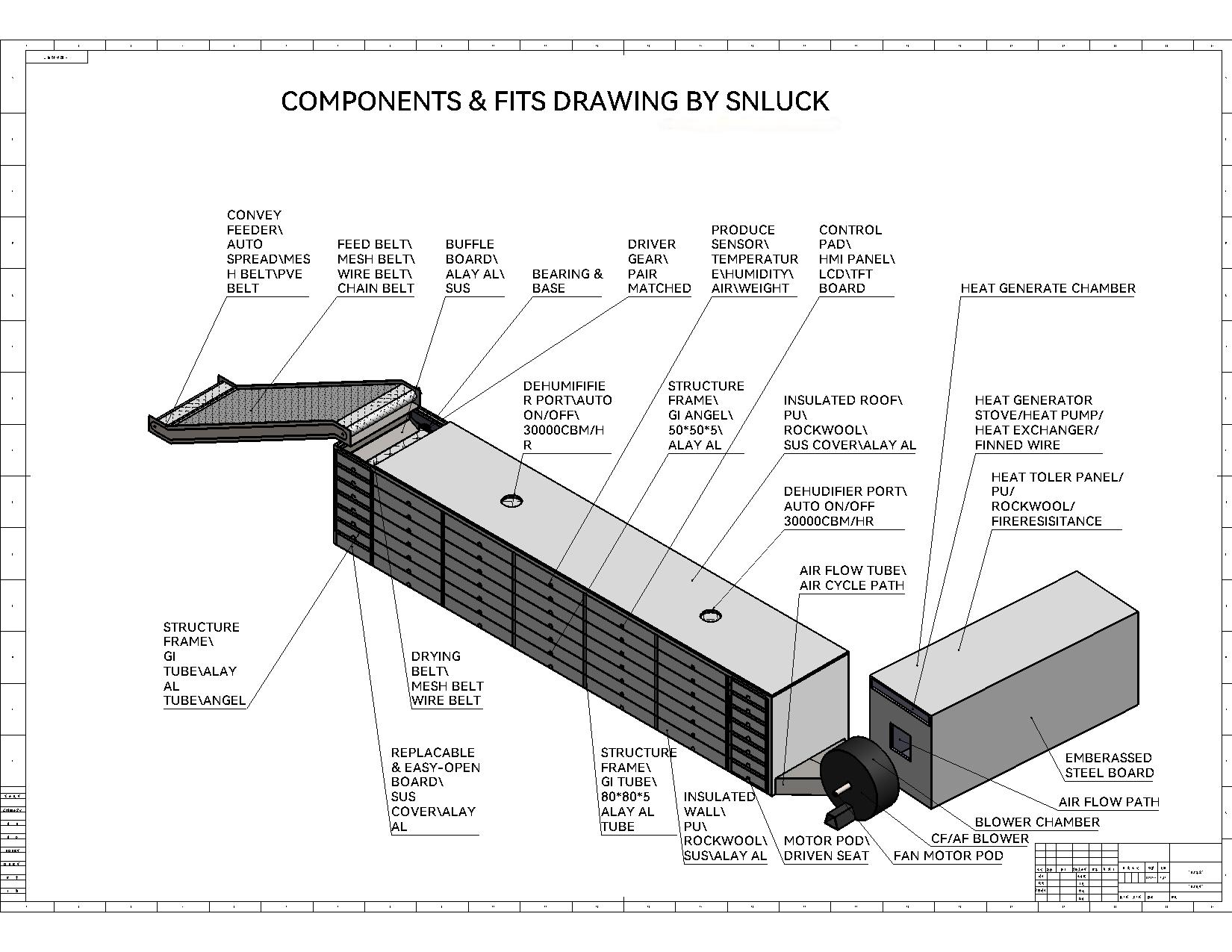

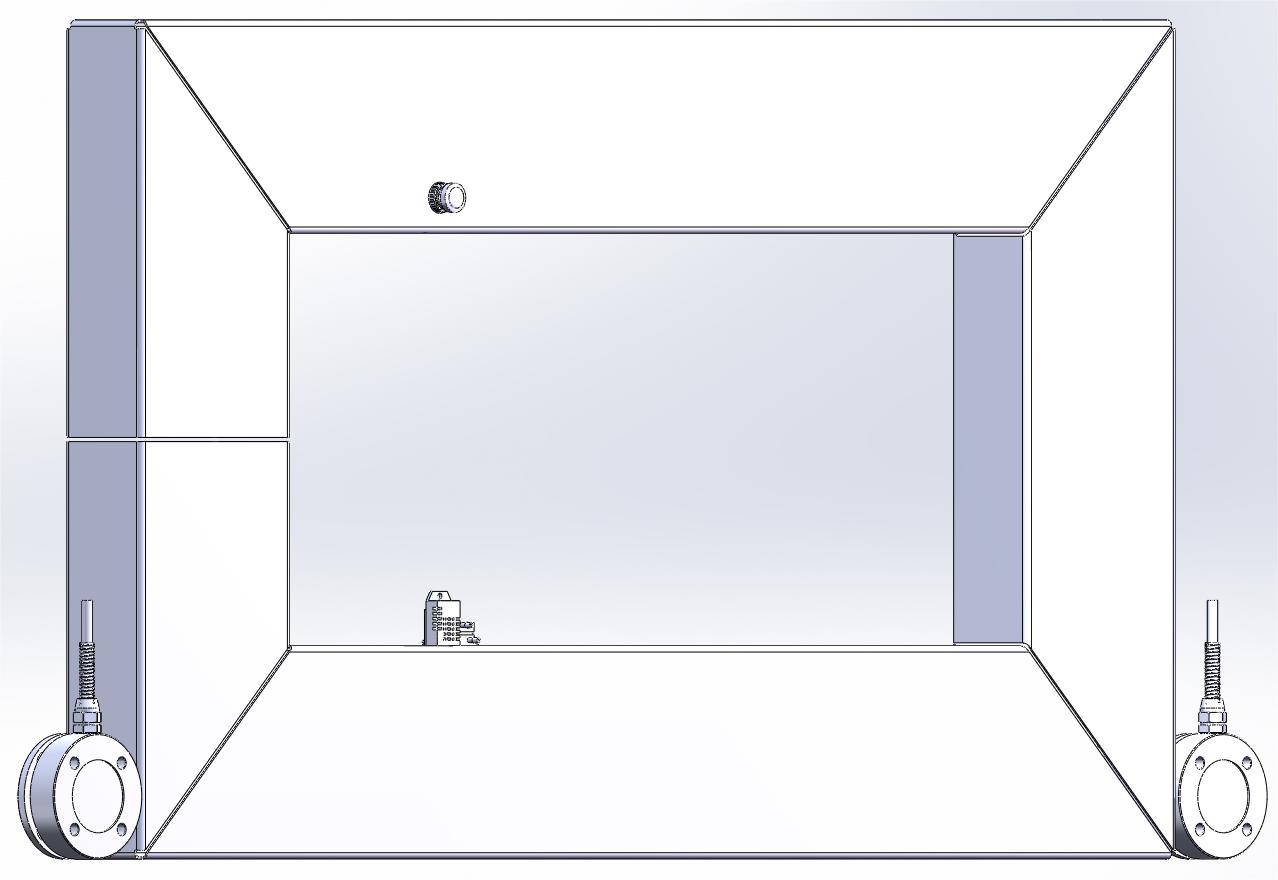

Streamlined Structure of Batch Tray Dryer -

Neat Modules & Parts

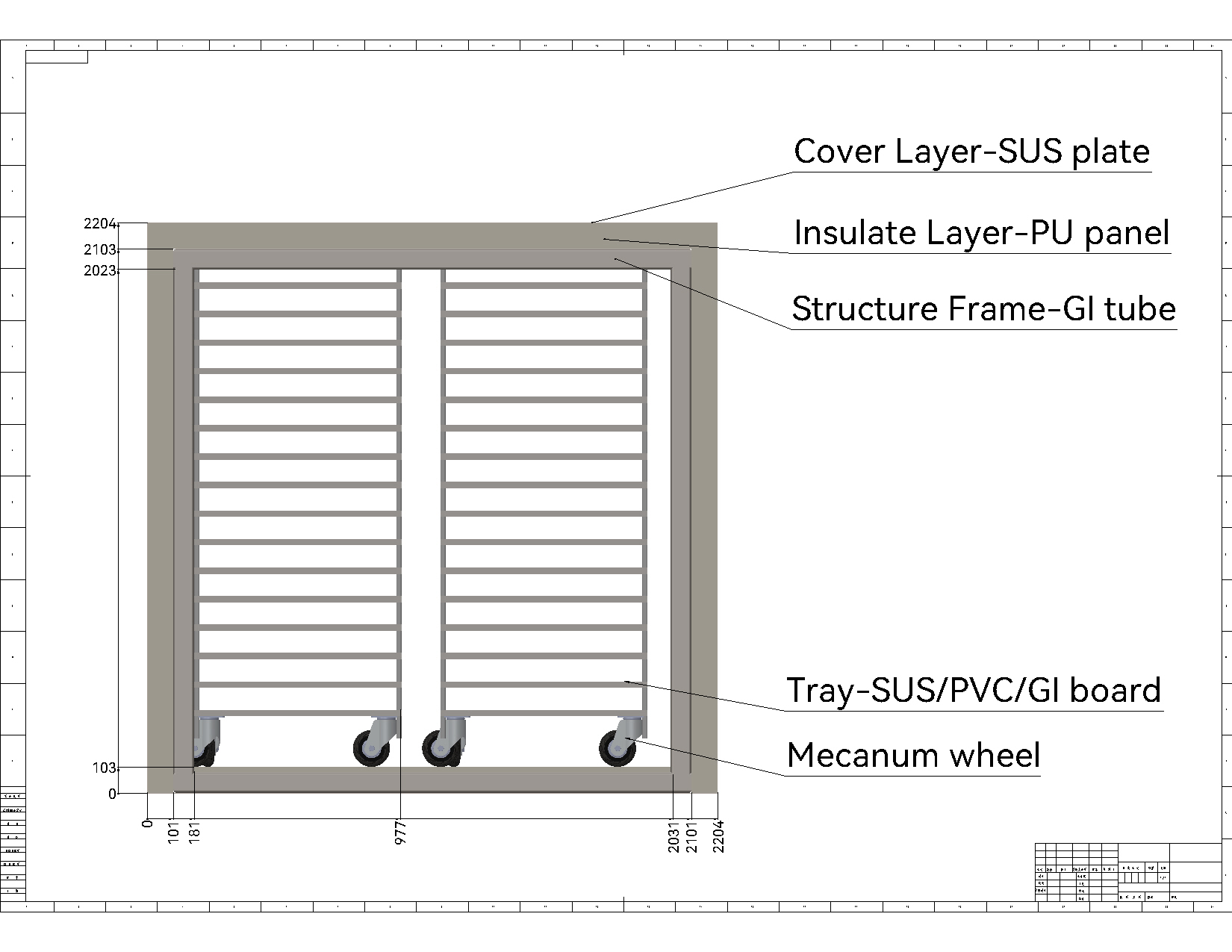

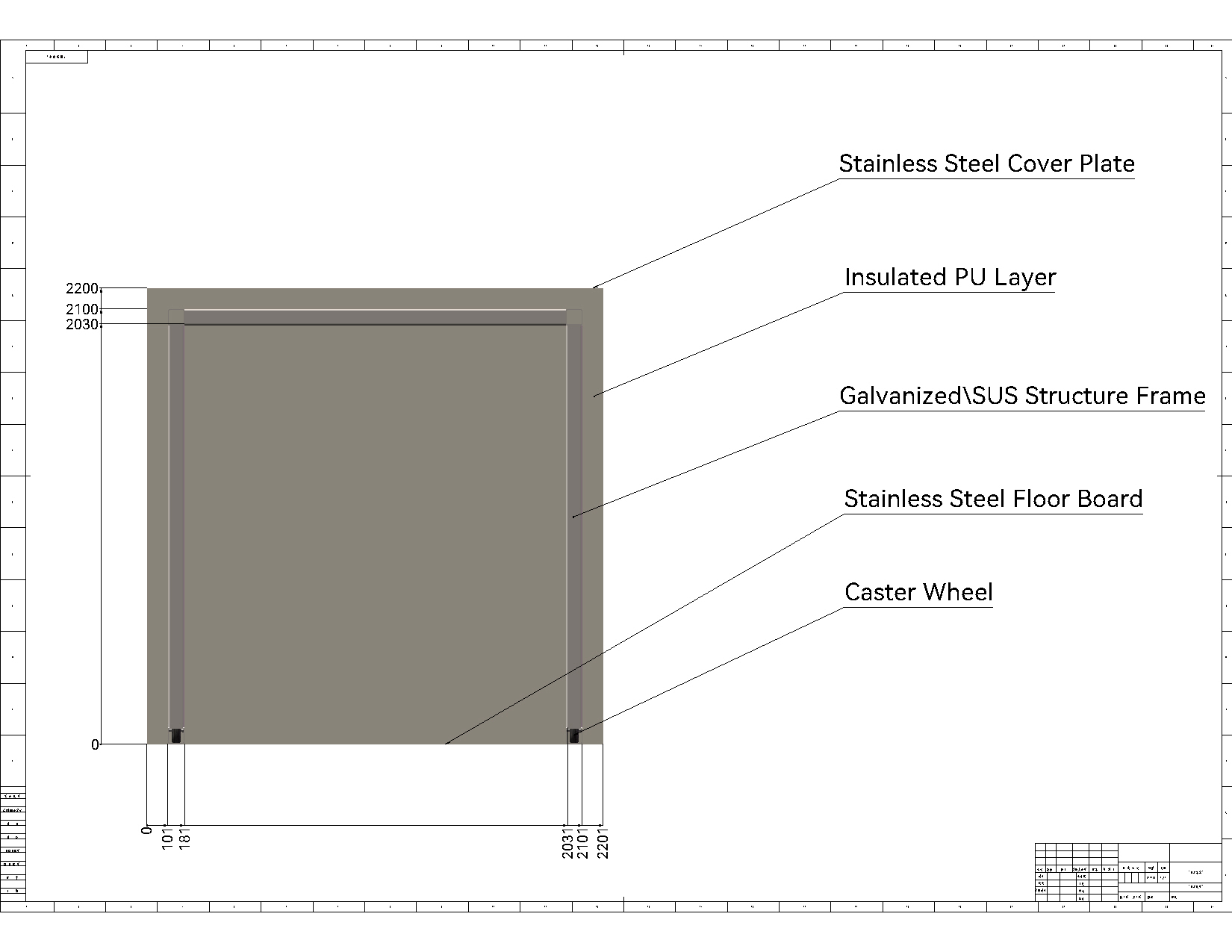

Models & Customization of Batch Tray Dryer -

Specification Comparison

Larger capacity & efficiency At same size: 11*2*2CBM dimension & 12*2sqm occupied area.

| Item | Standard Model SL-CRSX-52 | Rehanced Model SL-BPPX-L5 |

|---|---|---|

| **Regular Parameter** | ||

| Capacity | 400-800Kg/Full | 1200-2400Kg/Full |

| Hot Air Temp Range | 40-120℃ | -15-135℃ |

| Load Layers | 3-18 Layers | 3-18 Layers |

| **Structural Feature** | ||

| Valid Area | 100SQM | 250SQM |

| Thickness Loading | <25mm | <50mm |

| Module Assemble Period | 2Hr | 2Hr |

| **Heat Efficiency** | ||

| Heat Power Efficiency | 78% | 82% |

| Heat Recycle Ratio | 65% | 77% |

| **Control Accuracy** | ||

| Temp Fluctuation Control | ±2℃ | ±1℃(PID 2.0) |

| Humi Fluctuation Control | ±2%MC | ±1%MC |

The dehydrator is designed for ease of operation with user-friendly controls and automated features. Regular maintenance is required to ensure optimal performance, but detailed manuals and technical support are provided for hassle-free upkeep.

Hot air dehydrators provide faster drying times, better energy efficiency, and the ability to control the drying environment, resulting in superior product quality and longer shelf life.

Compared to other drying methods, the hot air dehydrator offers efficient moisture removal, consistent product quality, and adjustable drying parameters for precise control over the drying process.

Yes, the dehydrator can be paired with solar thermal energy systems, making it a sustainable option for drying processes that prioritize eco-friendly solutions.

The dehydrator operates by circulating hot air through the product, which removes moisture and dries the material. This process helps in preserving the product and extending its shelf life.