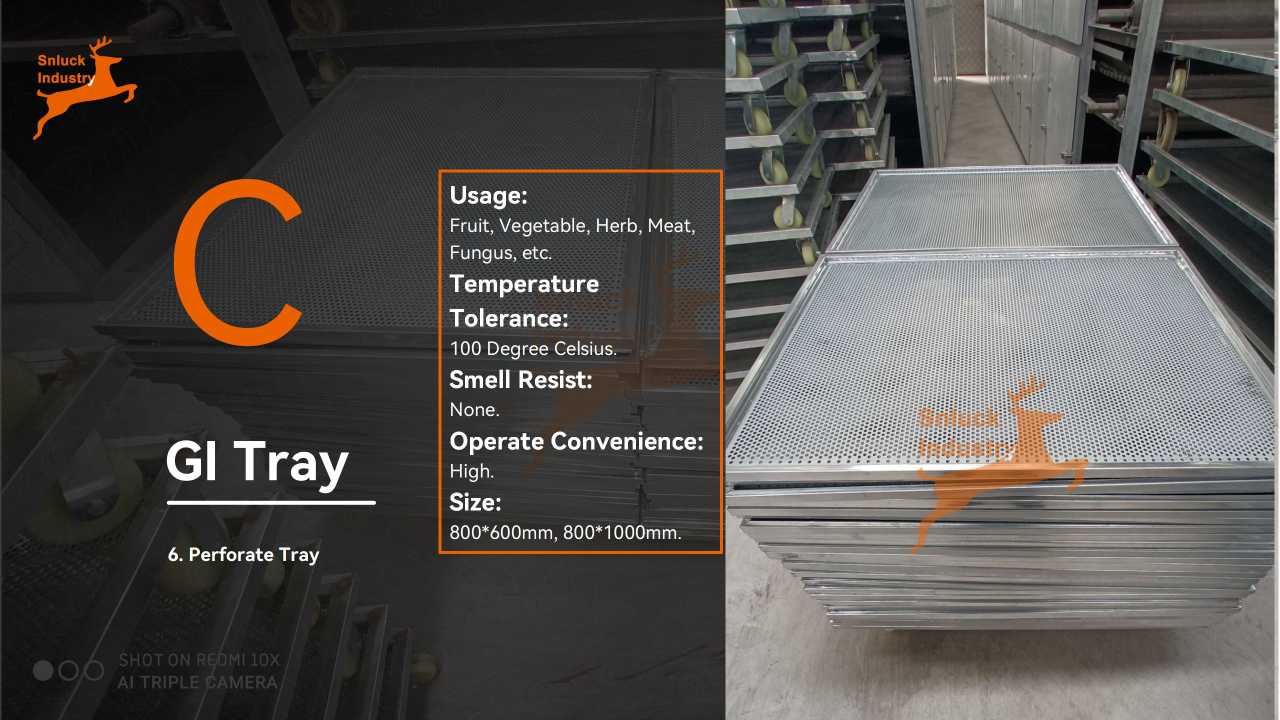

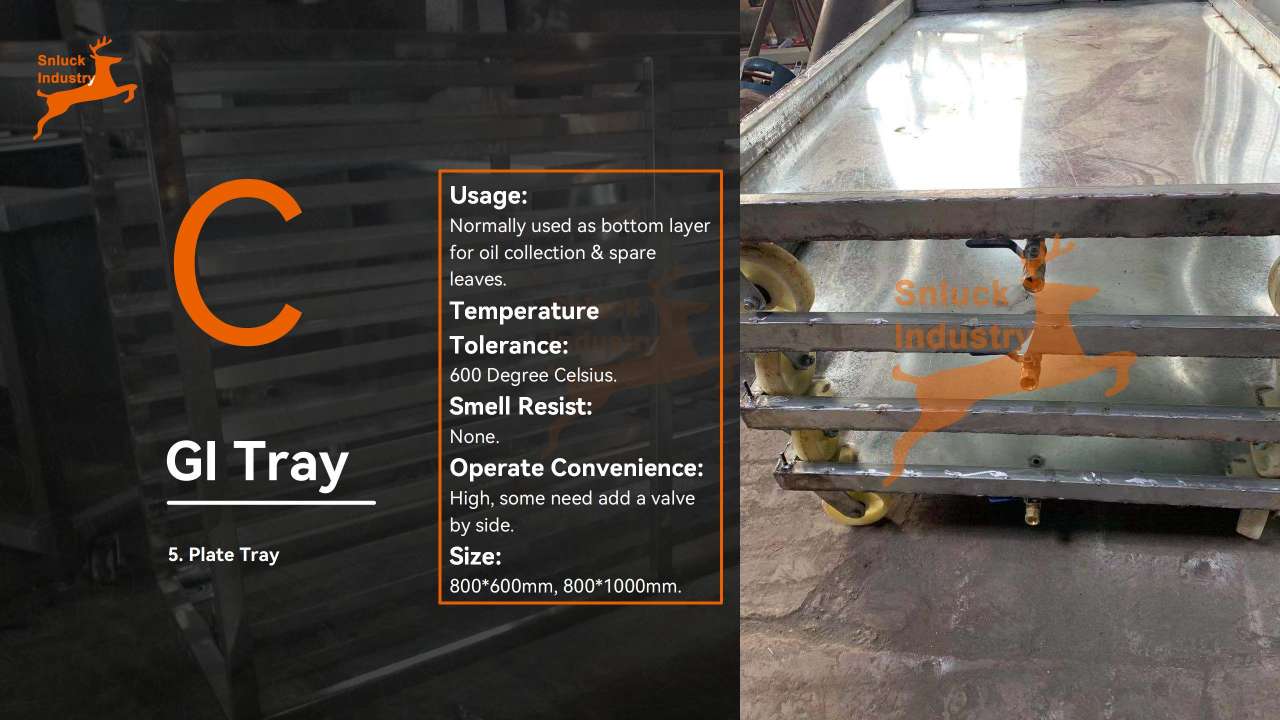

Trays

- Trays are the workhorses of the dehydrating process. They provide a flat, perforated surface for spreading your product in a single layer. This allows for maximum airflow throughout the product for even and efficient drying.

- Food-grade stainless steel is the preferred material for trays.

- Durability: Can withstand the high temperatures and humidity within the dehydrator chamber.

- Corrosion Resistance: Ensures long-lasting performance and prevents contamination of your product.

- Ease of Cleaning: Sanitary surfaces facilitate proper cleaning and hygiene practices.

- Design for multiple aims.

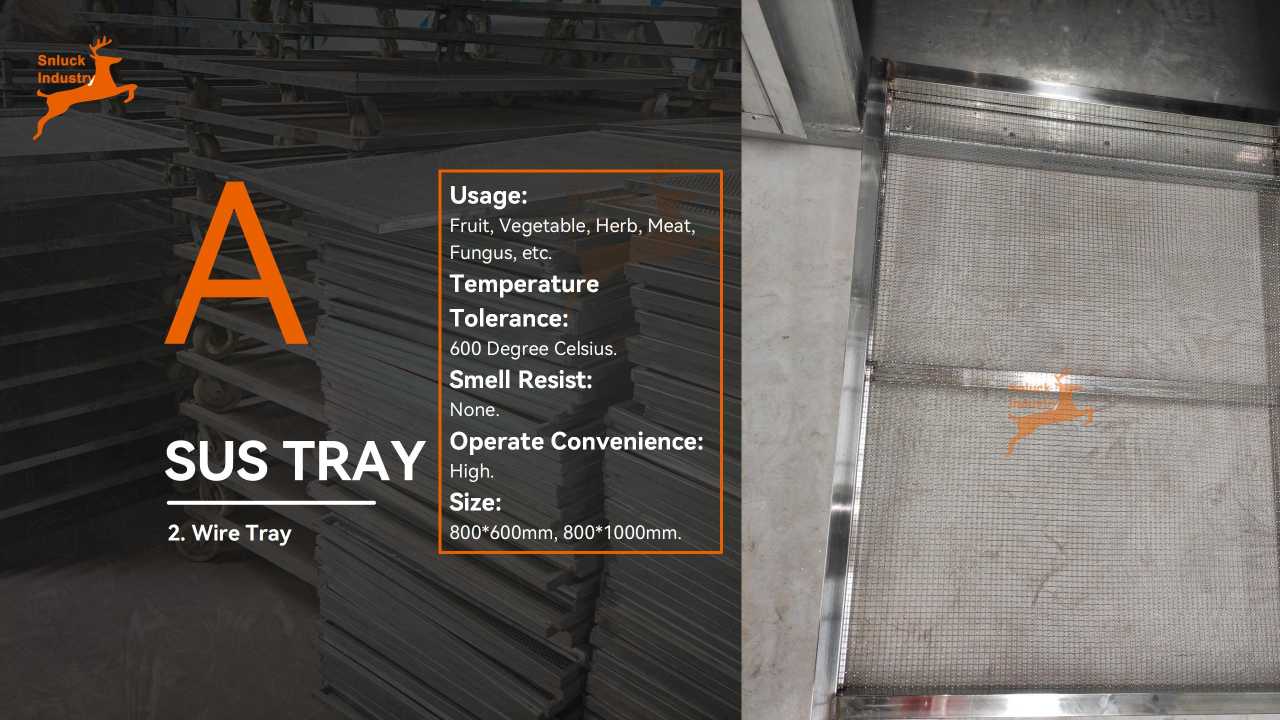

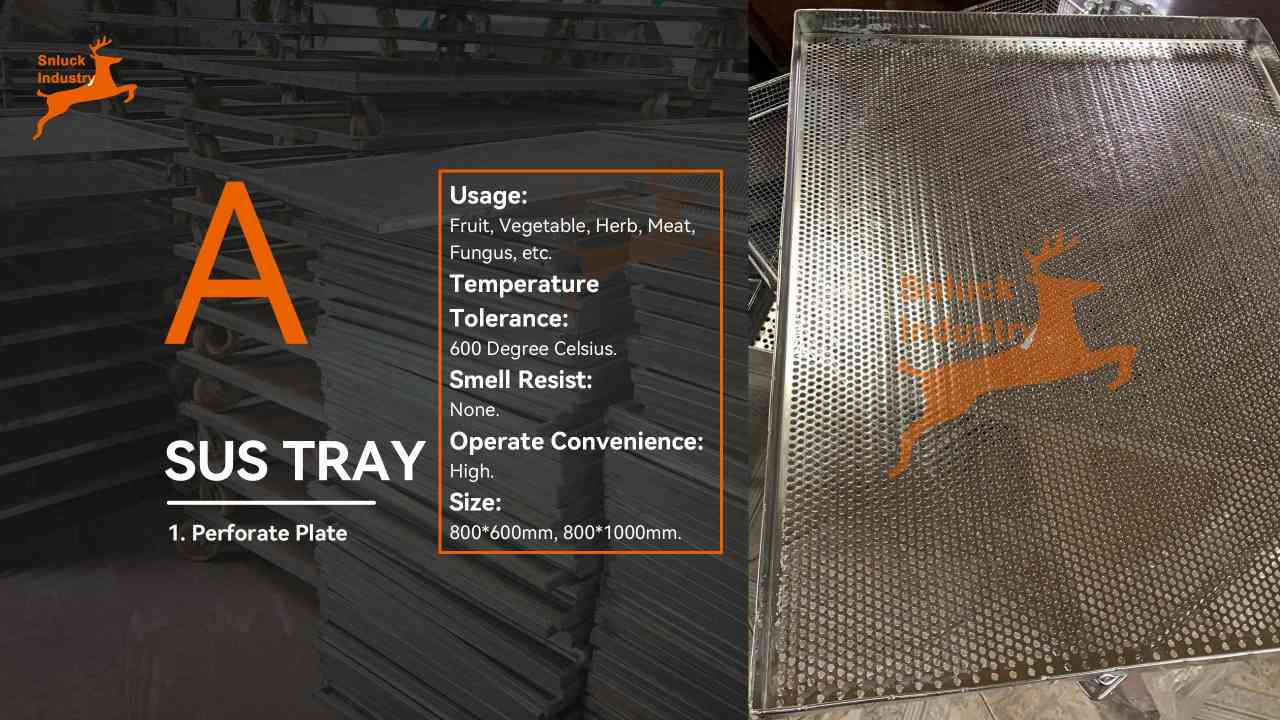

- Perforated or Mesh Bottoms: These are the most common types, allowing hot air to effectively pass through the product from below, promoting faster and more uniform drying.

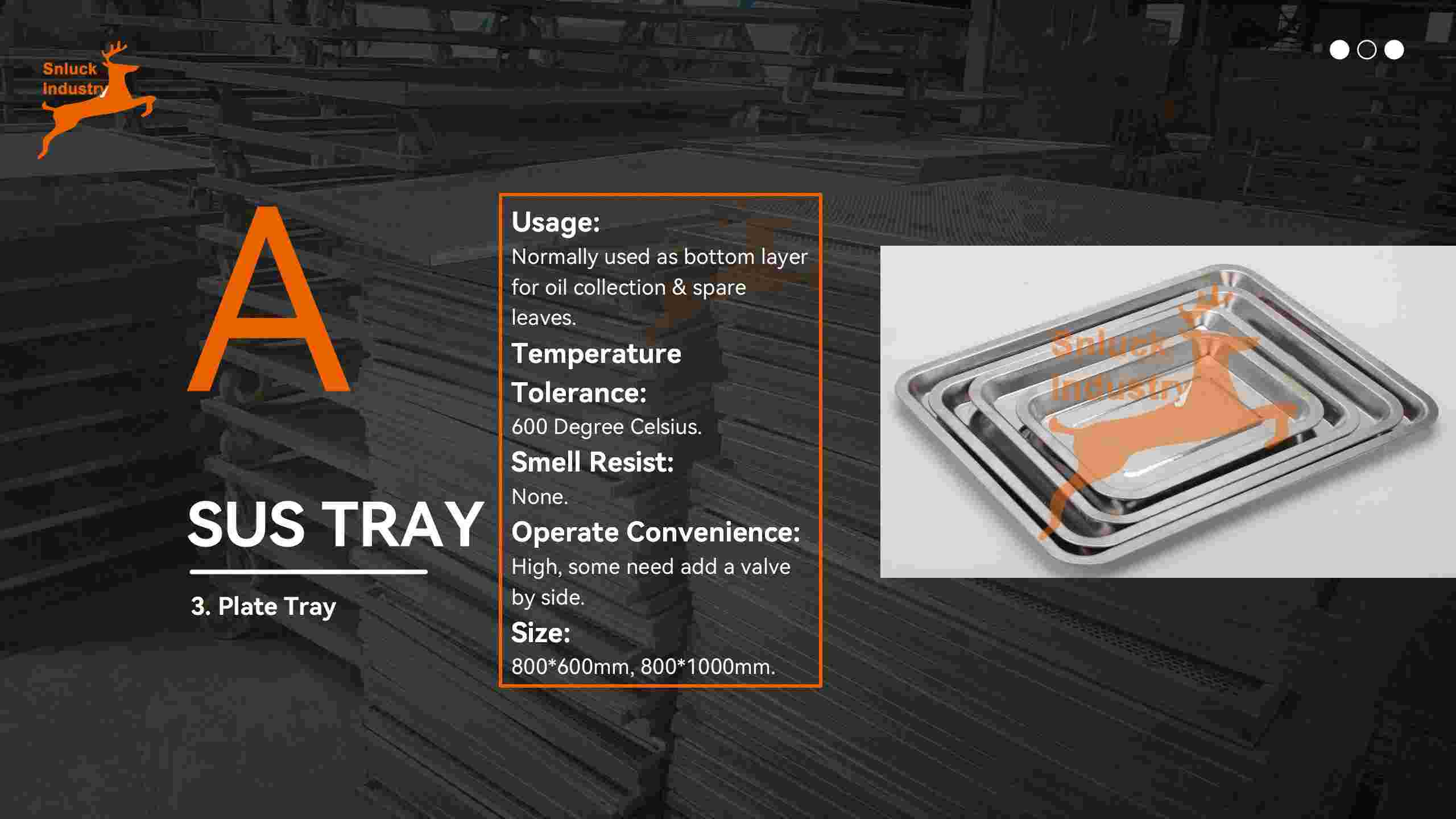

- Solid Bottoms: While less common, solid bottom trays may be used for specific applications like liquids or pastes that require a contained drying surface.

- Size and Capacity.

- Trays come in various sizes to fit different dehydrator models.

- Their capacity, measured in square footage or the amount of product they can hold, depends on the dehydrator size and the product being dried.

- Opt for trays that can comfortably hold your product in a single layer for optimal drying.

Trolleys

- Trolleys are mobile carriers designed to hold and transport multiple trays loaded with your product. They significantly improve loading and unloading efficiency within batch dehydrators.

- Trolleys are essentially multi-tiered racks with wheels.

- Multi-Tiered Racks: This design allows stacking several trays vertically, maximizing the number of trays loaded into the dehydrator chamber at once.

- Wheels: These enable easy maneuvering of loaded trolleys within the facility, reducing manual labor and saving time.

- Trolleys are often constructed from food-grade stainless steel.

- Durability: To withstand the weight of loaded trays and ensure long-term use.

- Hygiene: Maintaining a sanitary surface for safe food handling practices.

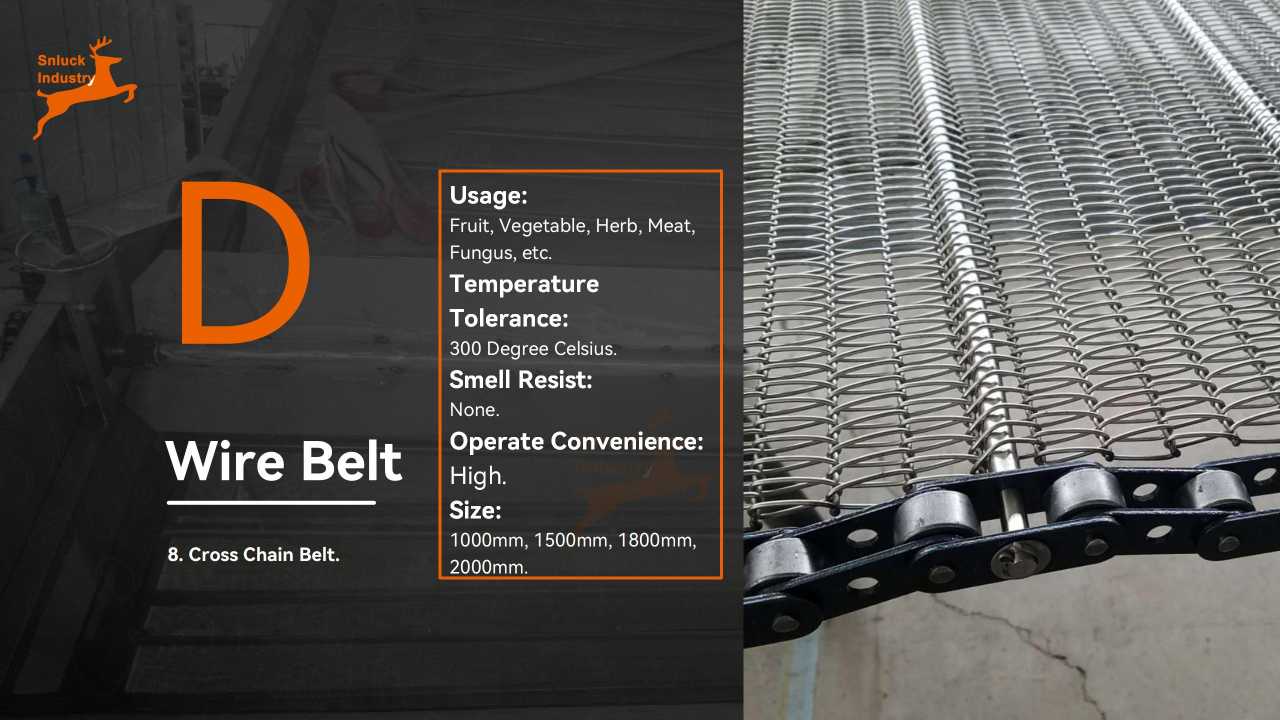

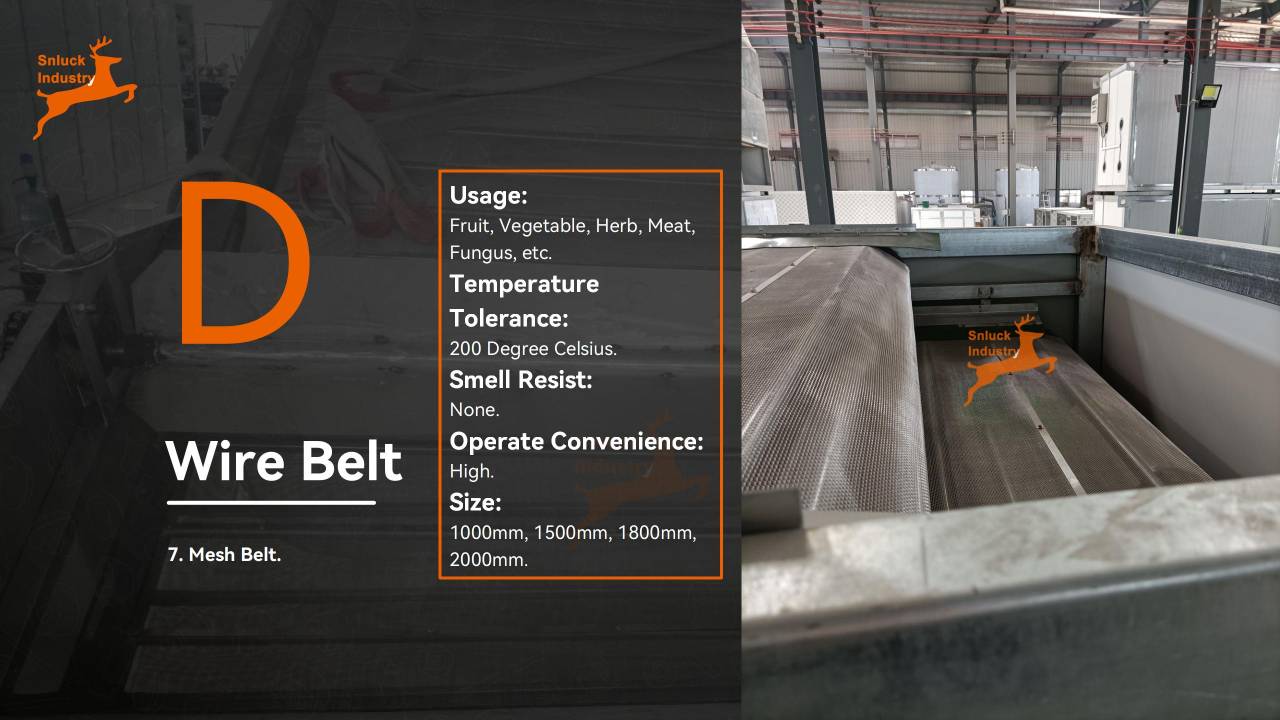

Conveying Belt

- In continuous dehydrators designed for high-volume production, the conveying belt acts as a moving platform that continuously transports the product through the drying chamber.

- Conveyor belts are typically made from food-grade mesh or other materials

- Air Circulation: Hot air can effectively reach the product throughout the drying process.

- Product Movement: The product can be continuously transported through different temperature zones within the dehydrator for efficient drying.

- The conveying belt moves at a controlled speed, ensuring the product spends the optimal amount of time in each temperature zone within the dehydrator. This allows for consistent and efficient drying of large volumes of product in a continuous flow.

- Conveying belts are specific to continuous dehydrators, which are ideal for large-scale production lines. They are not used in batch dehydrators, which rely on trolleys for tray movement.