Easy Use of Seperating Grater -

Instruction

- 1

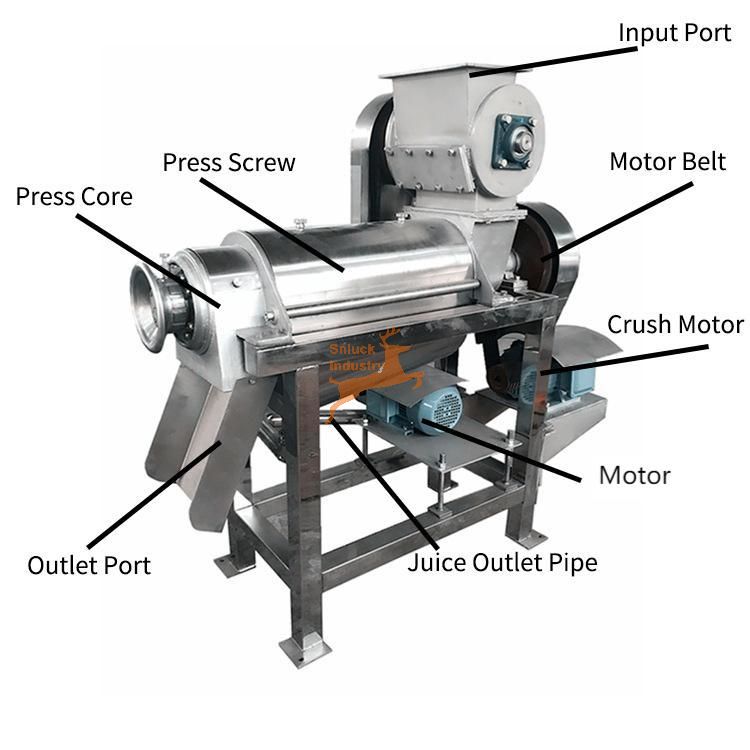

Preparation – Inspect the grater, ensure parts are intact, and install the blade correctly.

- 2

Feeding – Place materials evenly into the inlet to avoid overloading and clogging.

- 3

Operation Start – Switch on the power, let the grater run idle for a few seconds.

- 4

Crushing Process – Feed materials steadily, monitor the crushing effect to adjust feeding speed.

- 5

Separation Check – During operation, check if the solid – liquid separation works properly.

- 6

Cleaning – After use, clean the grater interior and blade to prevent material residue.

- 7

Maintenance – Regularly lubricate moving parts and inspect the blade for sharpness.