Breakage rate < 3%

Consumption 23% Less

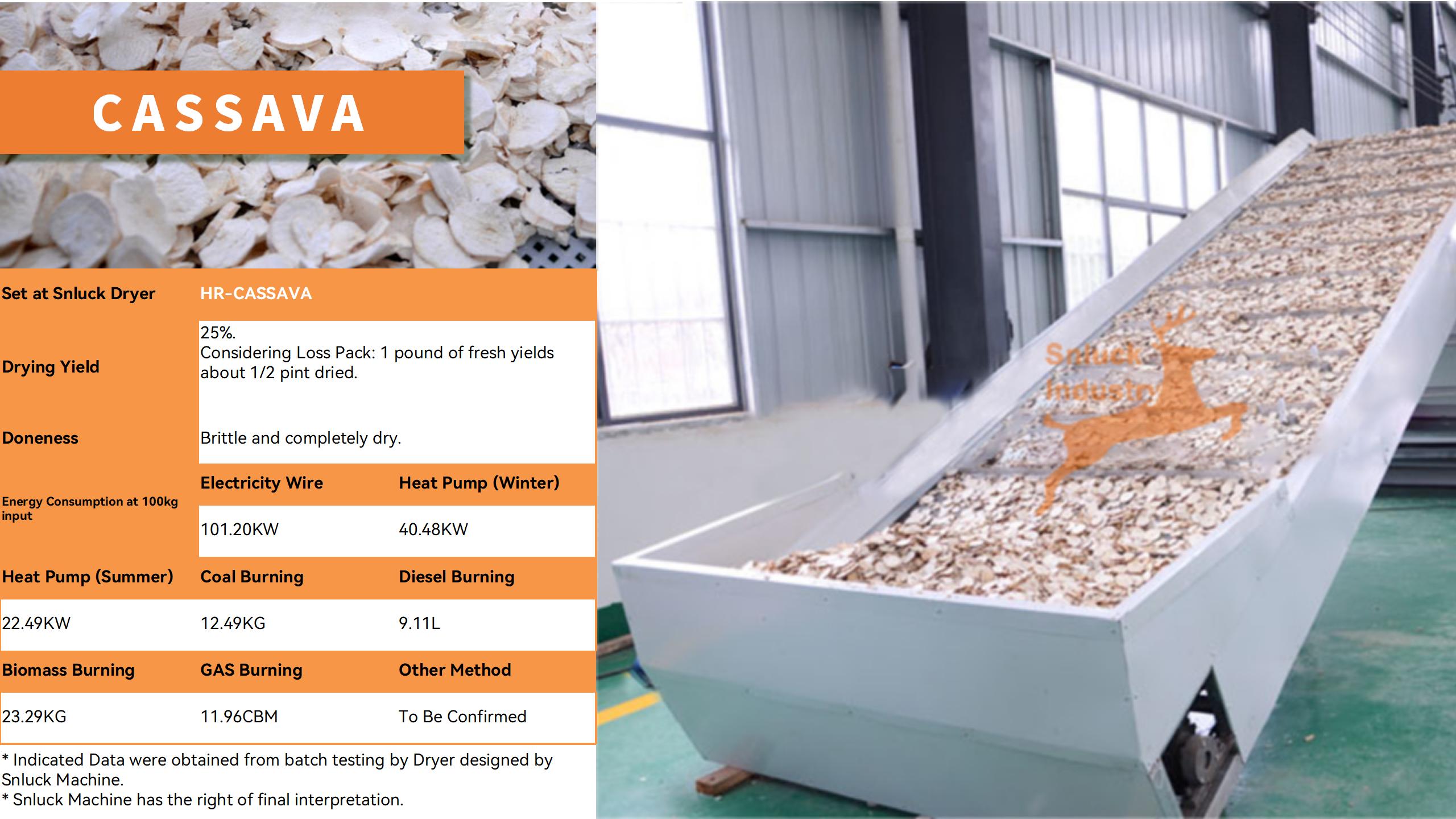

Auto feed & discharge – Continuous belt dryer for cassava drying

| Hot sale Model | SL-CSSA-L2 (200-400kg/hr input) |

|---|---|

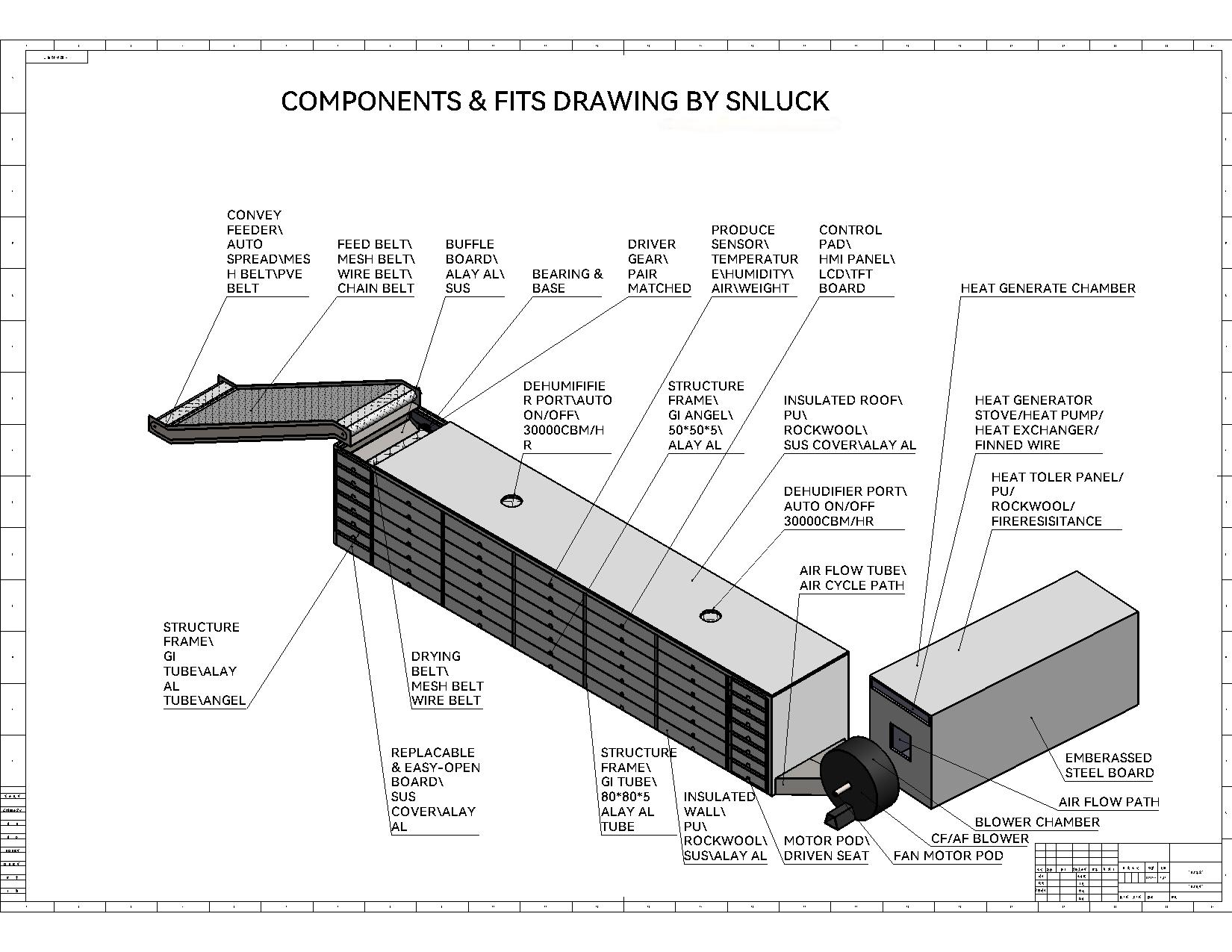

| Continuous Drying | Click to view-Continuous Belt type

|

| Module Compose | Click to view-Module Indication

|

| Size |

|

| Power |

|

| Yield Rate |

|

| Suggest for | High Grade or Continuous Process for industrial scale production. |

Tray load & discharge – Batch tray dryer for cassava drying

| Model | SL-BSSC-L4 (1000-2000Kg/Batch) |

|---|---|

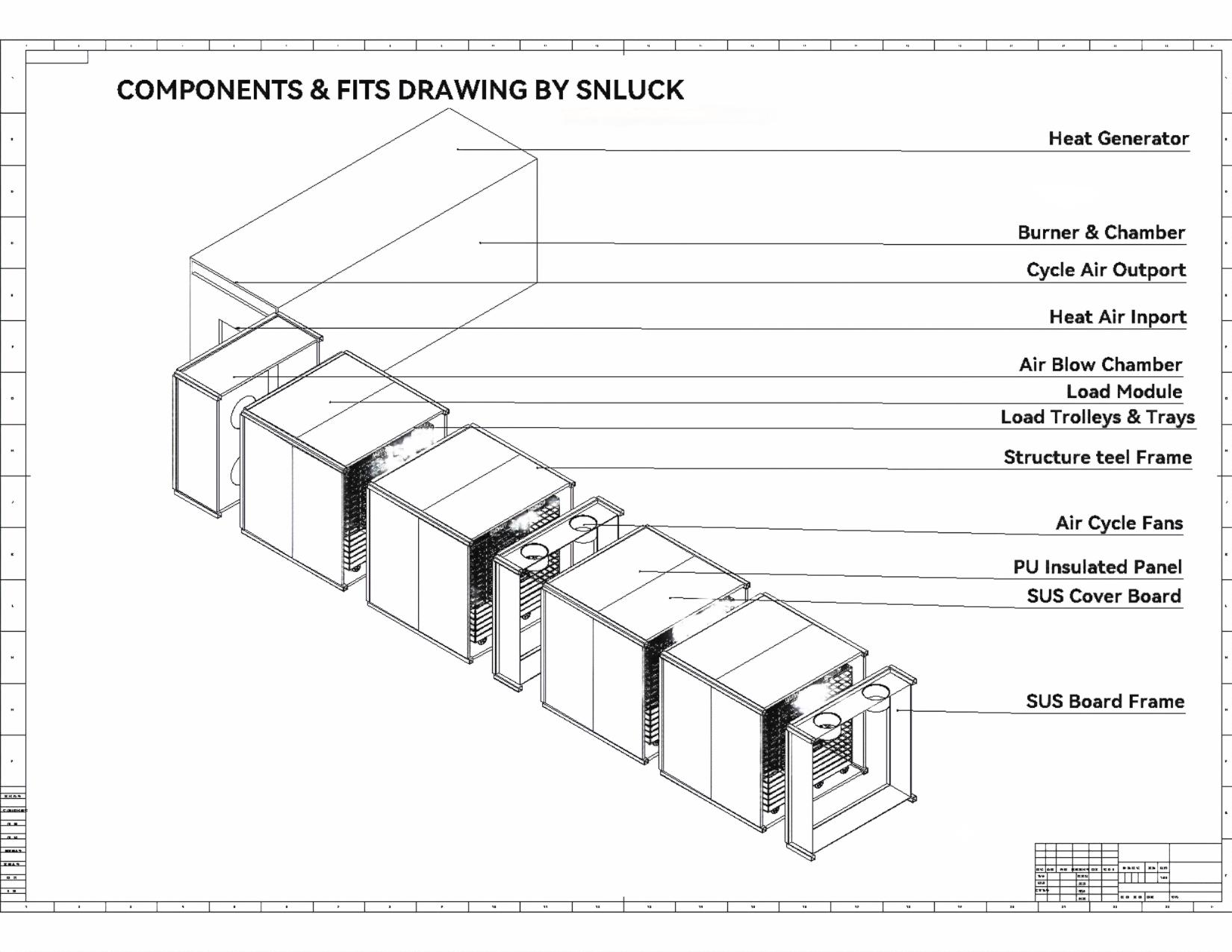

| Batch Drying | Click to view-Batch Tray type

|

| Module Compose | Click to view-Module Indication.

|

| Size |

|

| Power |

|

| Yield Rate |

|

| Suggest for | Trolley load & transfer stable drying production for multiple type materials. |

Support more than just Manufacturing

Service & Support

- 1

Seamless transaction: Minimizes administrative hassles for a smooth purchase.

- 2Timely delivery: Guarantees equipment arrival as scheduled for prompt production or operation start.

- 3Efficient installation and commissioning: Provides technical support for quick and correct equipment setup.

- 4Comprehensive training: The 15-day training equips users to operate and maintain the equipment effectively.

- 5Prompt technical issue resolution: Enables quick troubleshooting and minimizes downtime.

- 6Risk-free initial operation: The three-month trial operation helps identify and address potential issues for stable performance.

- 7Cost-effective maintenance: Offers maintenance advice and cost-effective spare parts and servicing.

- 8Continuous improvement: Enhances equipment and services based on feedback for better value.

- 9Long-term partnership: Builds a reliable relationship for ongoing support and mutual success.